SYSTEM MODULE Additional Solutions

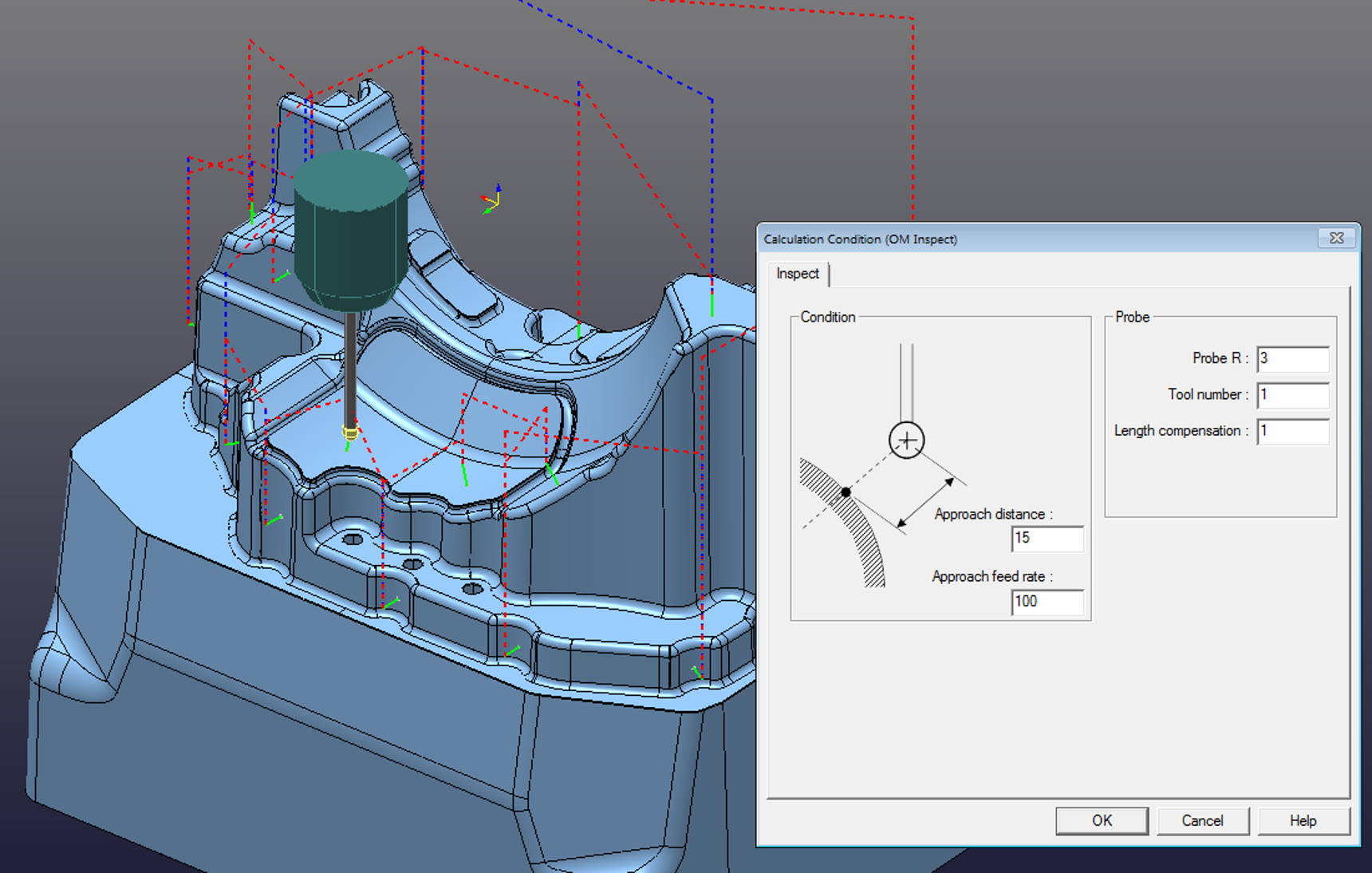

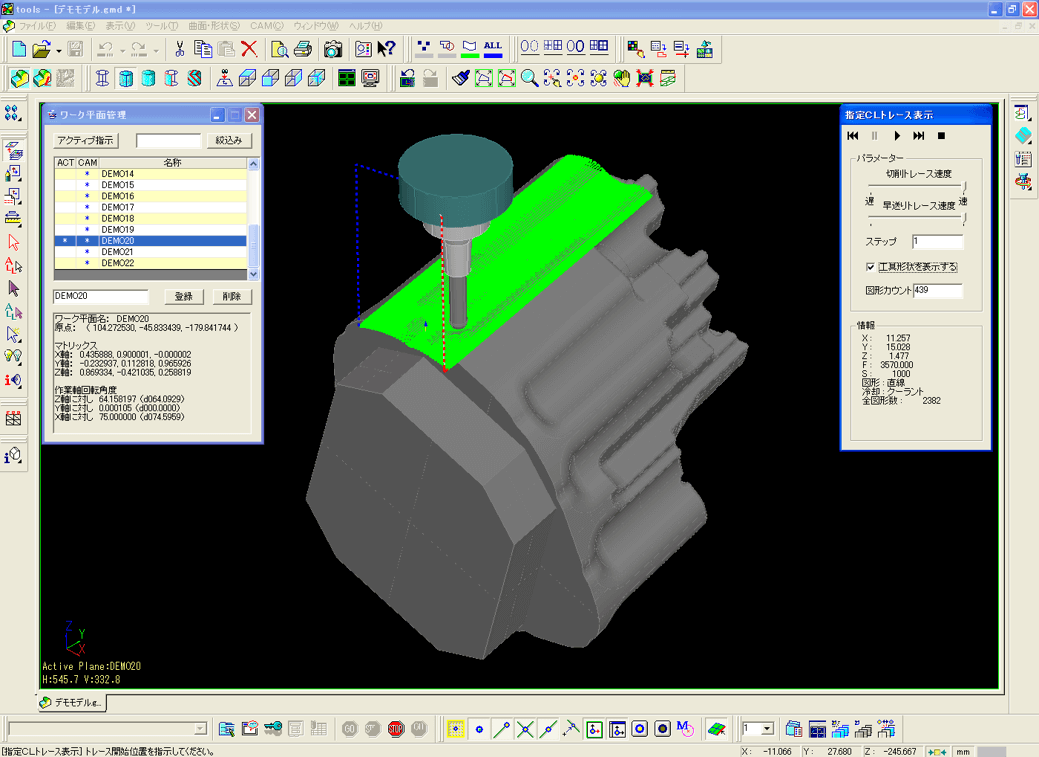

Measurement(OM Inspect)

Automatic measurement of curved surfaces in machining suppresses inspection setup

This is the command for inspecting the machining precision directly on a machine. Accurate inspection is possible by using the same system for both creating machining data and setting points to inspect. Outputting an inspection result into a file is also available.

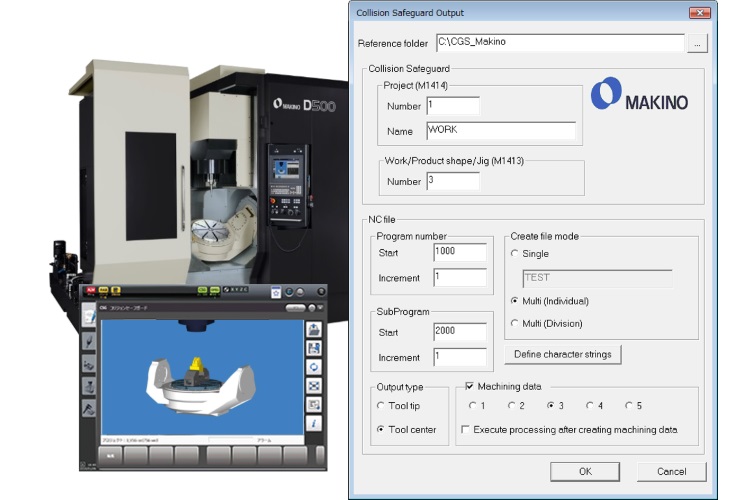

MAKINO Collision Safe Guard I/F

Quickly with the seamless environment,“Collision Safeguard” files can be generated !!

"MAKINO Collision Safe Guard I/F" is the output module for "Collision Safeguard", monitoring & preventing function for machining collisions, equipped in "Professional 6" controller. The seamless operational environment has been achieved by the close collaboration between the systems, enabling CAM-TOOL to quickly generate the files for "Collision Safeguard".

* Please contact Makino Milling Machine Co., Ltd. for the details of “Collision Safeguard”.

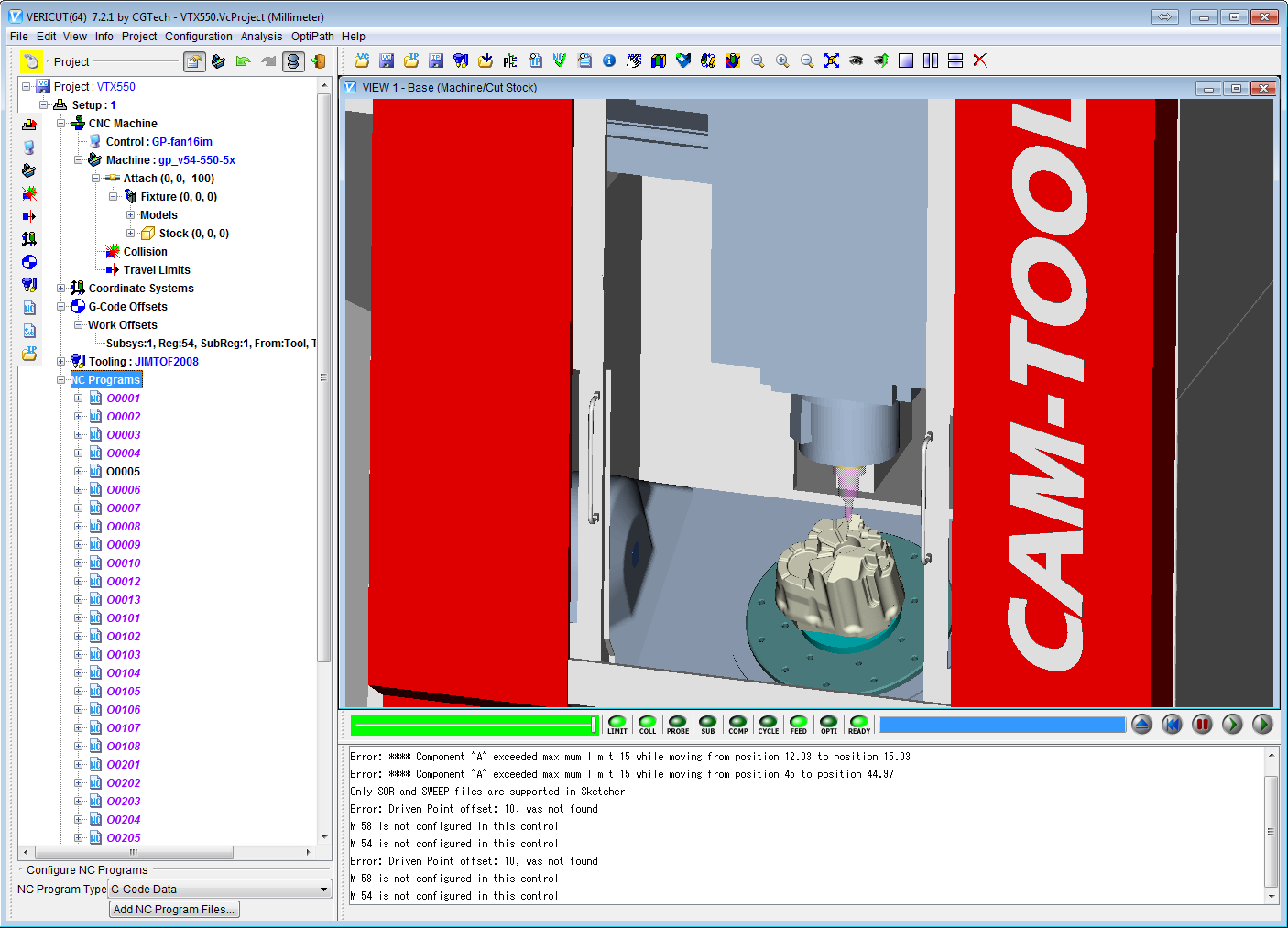

VERICUT Interface

Seamless connection to VERICUT !!

"VERICUT Interface" provides seamless operability from CAM-TOOL to VERICUT. It starts from Vericut Icon in CAM-TOOL then exports data of tooling (tool and holder), NC program name, tool number into VERICUT automatically. Especially, at the simultaneous 5 axis machining, it will realize safe and effective machining by checking all of interference of machine tool.

* VERICUT®is a registered trademark of CGTech, Ltd.

Calculate Machining Time(ESTIMATE)

Advance prediction of machining time with an error range within ± 10%

Analyze NC data and predict machining time with ± 10% time error.

* Please inquire for compatible models and details.

3D Mouse

3Dconnexion SpaceMouse®

This assists CAM operations that often involve zooming in and out of views, such as checking gaps between surfaces to be machined, steps and paths.

※CAM-TOOLは、Certified by 3Dconnexion.

CAM-TOOL Prime

Special Specification: 3D CAM system for overseas production sites

"CAM-TOOL Prime", 3D CAM System for professional,

addresses the sophisticated requirements of global leaders in Mold & Die Industries

by offering unparalleled functionality using our powerful NC programming strategies

that simply do not exist in other systems.

*It is a packaged product for overseas local companies that are equipped with a proven CAM engine and pursuing standardization and level equalization of operations.

*This system is limited to English and Chinese.

CAM-TOOL BaseZero

Special Specification: Viewer system focused on the field

"CAM-TOOL BaseZero" is a viewer package for CAM with the same GUI as CAM-TOOL. Models and data to be machined are received from the design and CAM departments, and machining information such as shape, dimensions, position and cutter path can be easily checked at the site terminal. If the NC post conversion function is added (Options), it is possible to output all data on the field side without using CAM department. In addition, IGES, DXF and STEP inputs are provided as standard equipment so that they can be used not only for field use but also when discussing specifications with the supplier.

Product Inquiry

Contact us