SYSTEM MODULE Base / Modeling

Base Module

Powerful support for deployment from product models

Basic CAM-TOOL module. The IGES/DXF/STEP input/output and STL input come standard and can be used to verify and edit the imported model data. It is also equipped with functions that can be linked to the CAM process, such as information necessary for tool selection.

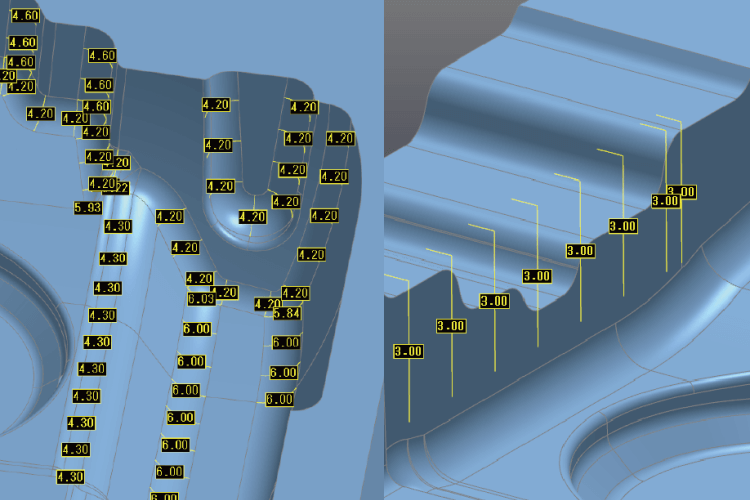

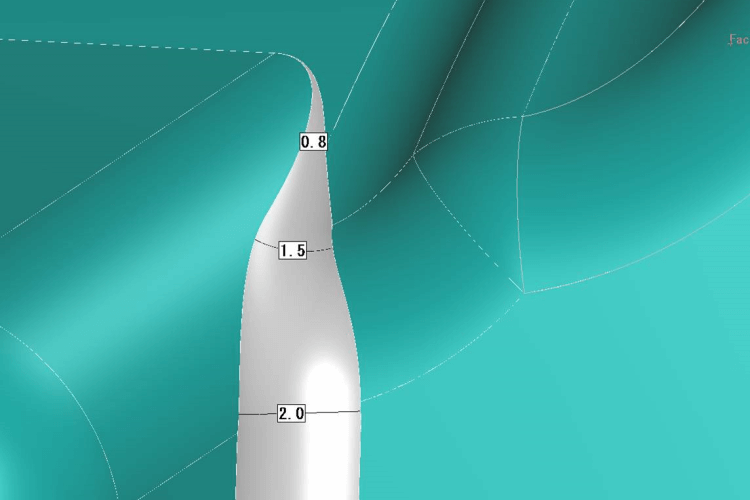

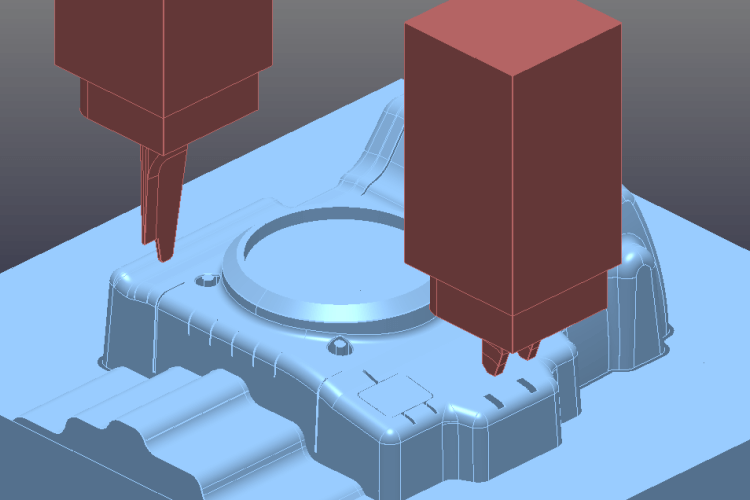

Fillet Surface Radius Info / Draft Info

Checking easily for fillet radius of the shape & draft angle from the machining direction helps to decide the shank and protruding length of the tool.

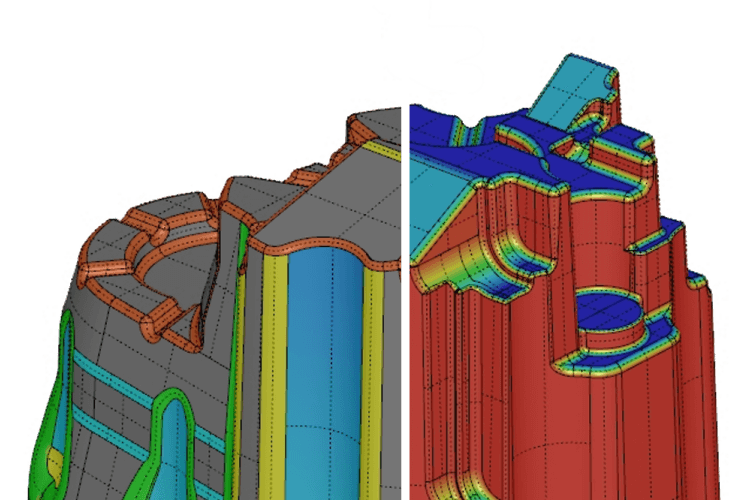

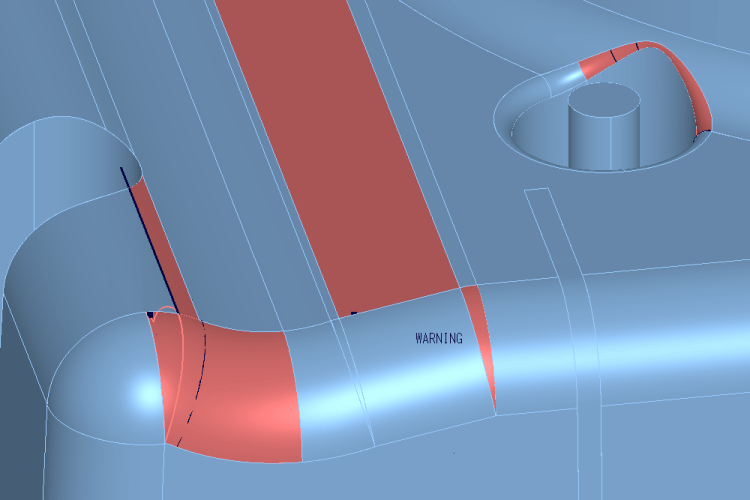

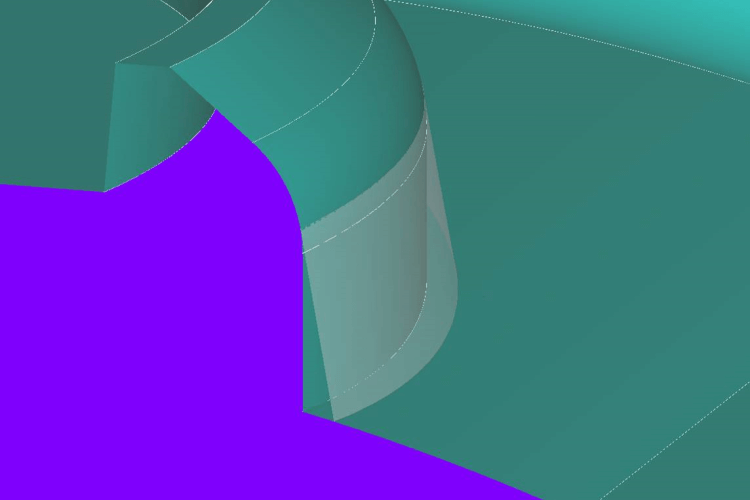

Curvature Radius/Angle Shading

Surface curvatures and angles are shaded by color maps. Shape-info such as fillet R’s or tapers can be evaluated easily, contributing to ease of cutting-tool selection.

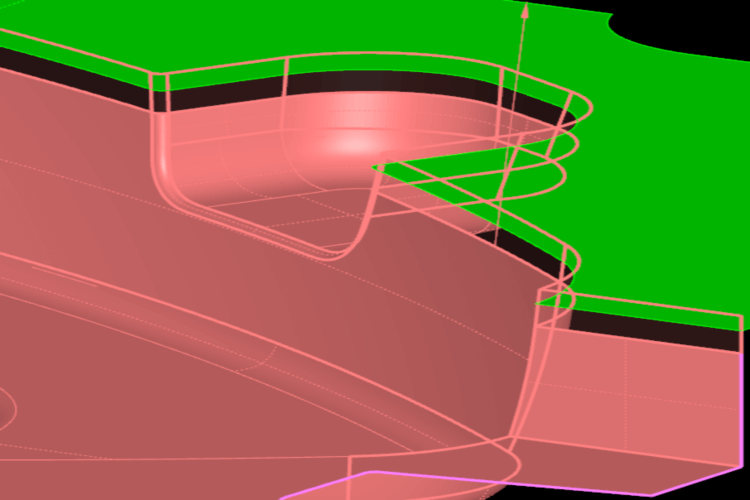

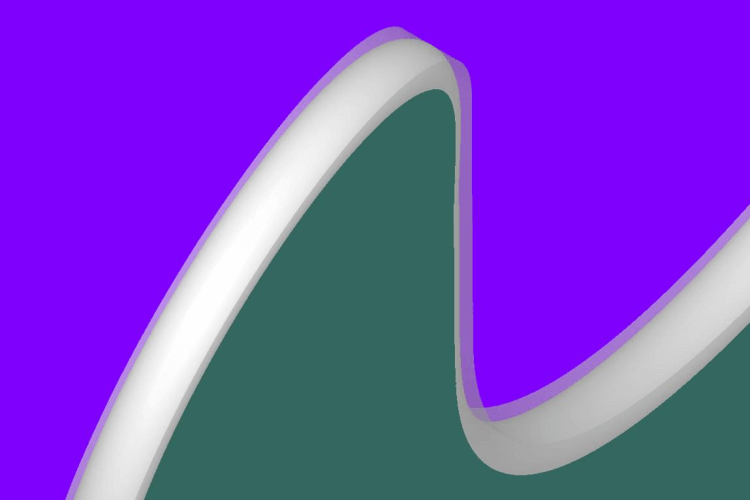

Expand Surface

[Specifying plural surfaces] & [Auto extension for trimmed surface] have available in “Expand Surface”, Prepared some types for expanding. Results of expanding can be confirmed in advance by pre-view in advance, which enables to reduce operation time for modeling.

Check Surface

Verifies imported surface, and detects & revises defective surfaces automatically.

Modeler Module

Equipped with various curved surface processing functions for shape processing specific to mold/die modeling

"Modeler" uses a unique surface modeler that is superior to CAM. It is equipped with a variety of curved surface processing functions to cope with the special shape processing of mold models, and it can quickly and easily handle the advanced modeling processing indispensable for machining.

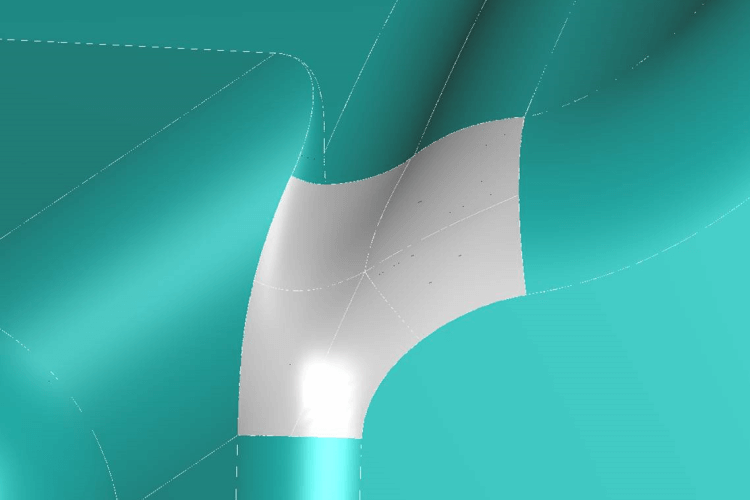

Variable Fillet Surface

Creates variable fillet surface by specifying radius at multiple portions.

N-Side Compensate Surface

Easily creates compensation surfaces at complicated portion.

3-Tangent Fillet

Creates a fillet surface tangent to 3 surfaces or curves.

Incline Surface

Creates a tapered surface that touches a curved surface at a specified angle.

Surface Plus Module(Option)

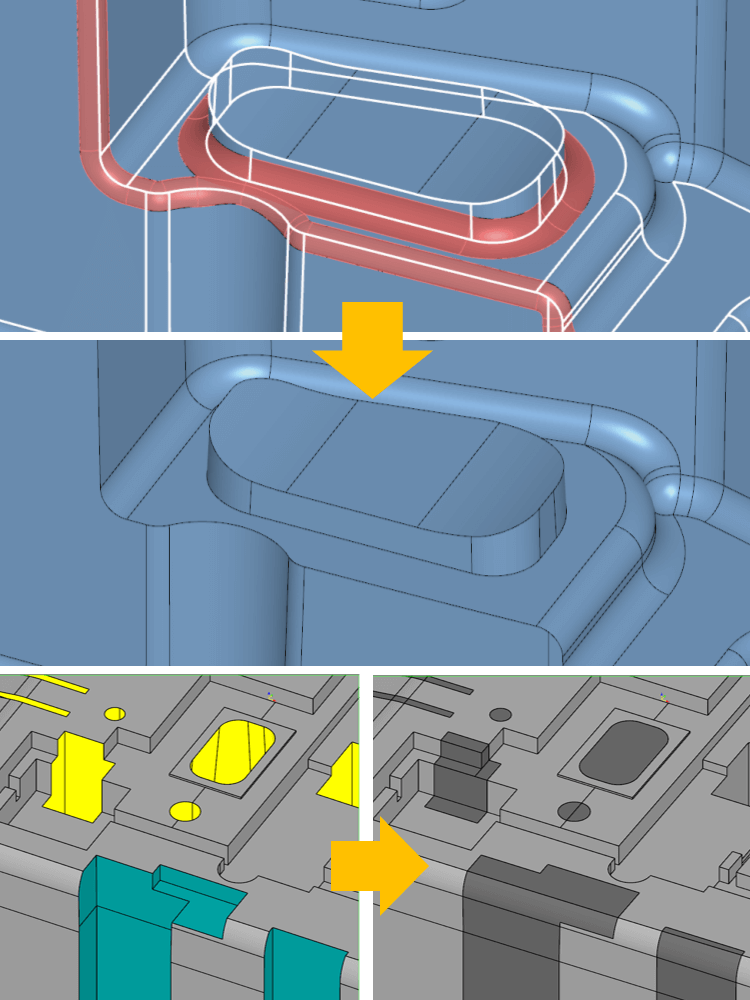

Surface Editing like Solid Modeler

[Delete Surface/Move Surface/Boolean Trim/Fill Surface] functions, which enable the modeling work by the similar operations to those of solid CAD systems, have been developed. The labors of necessary model editing as the preparation for CAM operation can be drastically reduced.

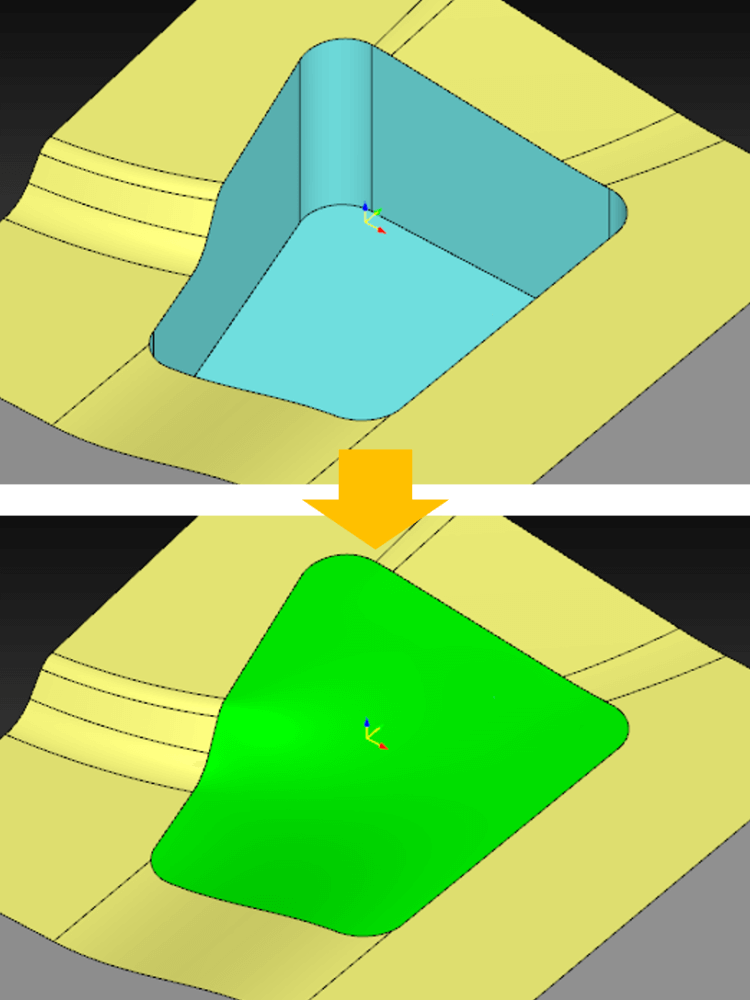

Delete Surface

Move Surface

Boolean Trim

Fill Surface

Operation example

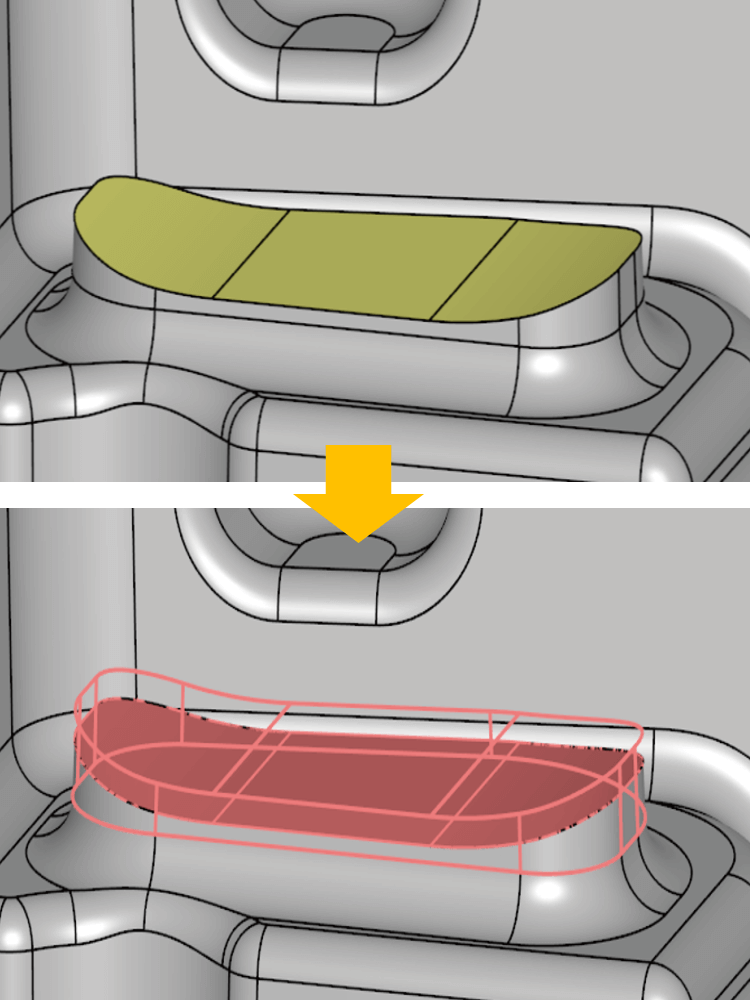

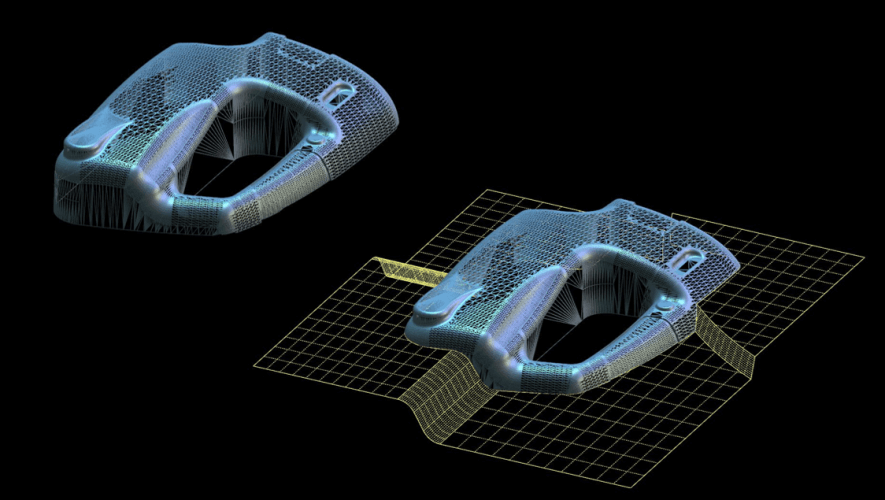

Edit Polygon Module(Option)

STL editing is unbeatable in CAM-TOOL !!

It is possible to inspect and modify STL data in CAM-TOOL.It greatly reduces CAM operation time using STL data in comparison to operating multiple CAD /CAM systems.

*This function is an option from V15.1.

Operation example

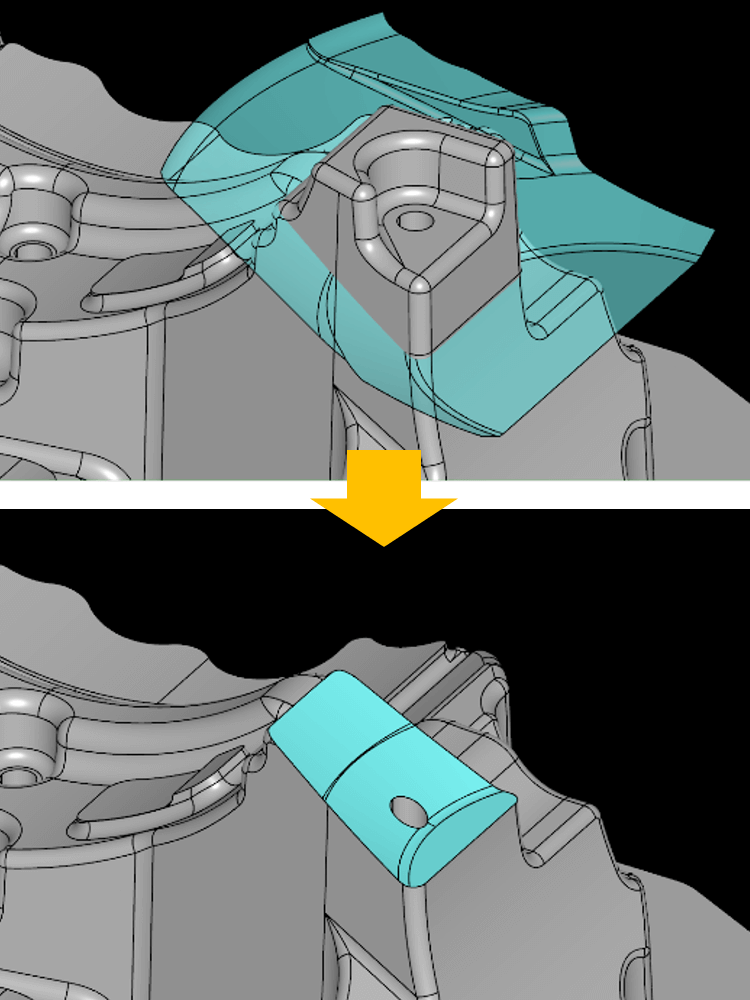

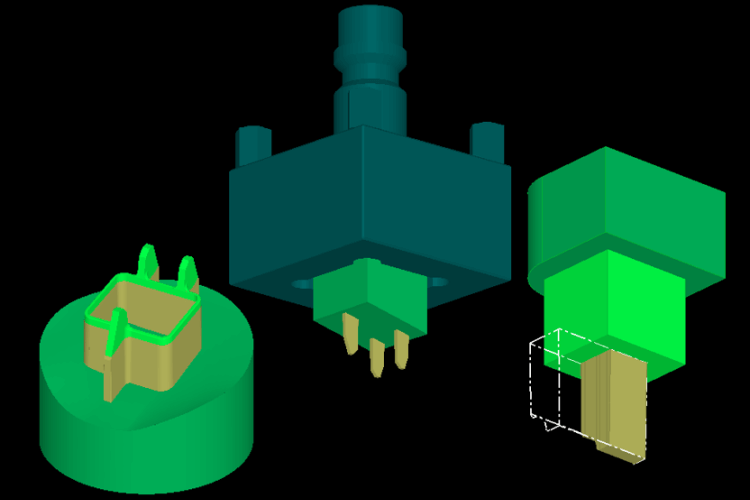

Create Electrode Module(Option)

Rich and versatile functions that take advantage of surface modeling

It extracts electrode shape from working model, and has a wide variety of functions like “Fill in blank”, “Fluctuation offset”, “Interference check”, “Process sheet” and etc. EPX format also can be output.

Data Translate Module(Option)

High quality translation for most famous native CAD systems.

Reliable data translation from other CAD systems supports a smooth translation for modeling work.

- IGES Import / Export

- DXF Import / Export

- STEP Import / Export

- STL Import / Export

- CATIA Import / Export

- Parasolid Import / Export

- CADmeister Import

- NX Import

- SOLIDWORKS Import / Export(Pulgin)

* CATIA is a registered trademark of Dassault Systemes.

* CADmeister is a registered trademark of Nihon Unisys, Ltd.

* SOLIDWORKS is a registered trademark of SolidWorks Corporation.

* NX and Parasolid is a registered trademark of SIEMENS Corporation.

Product Inquiry

Contact us