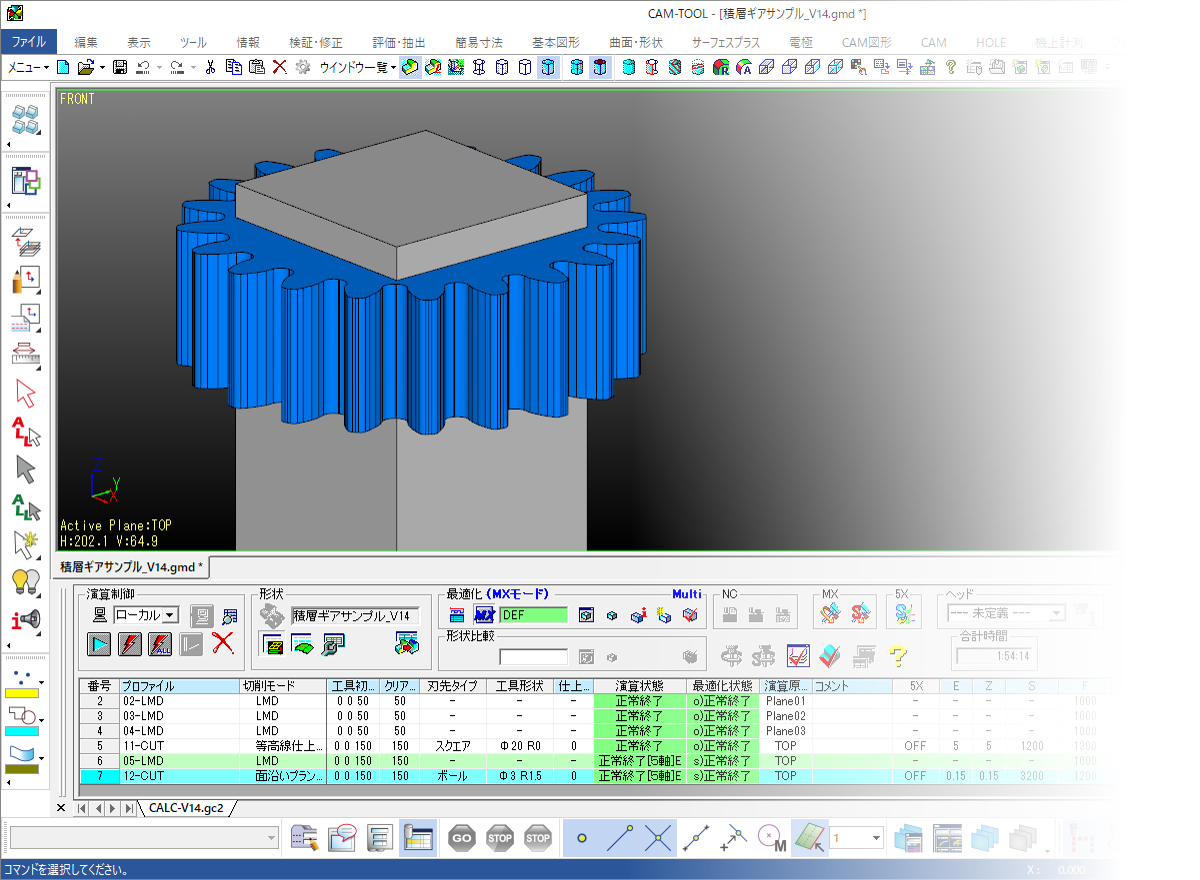

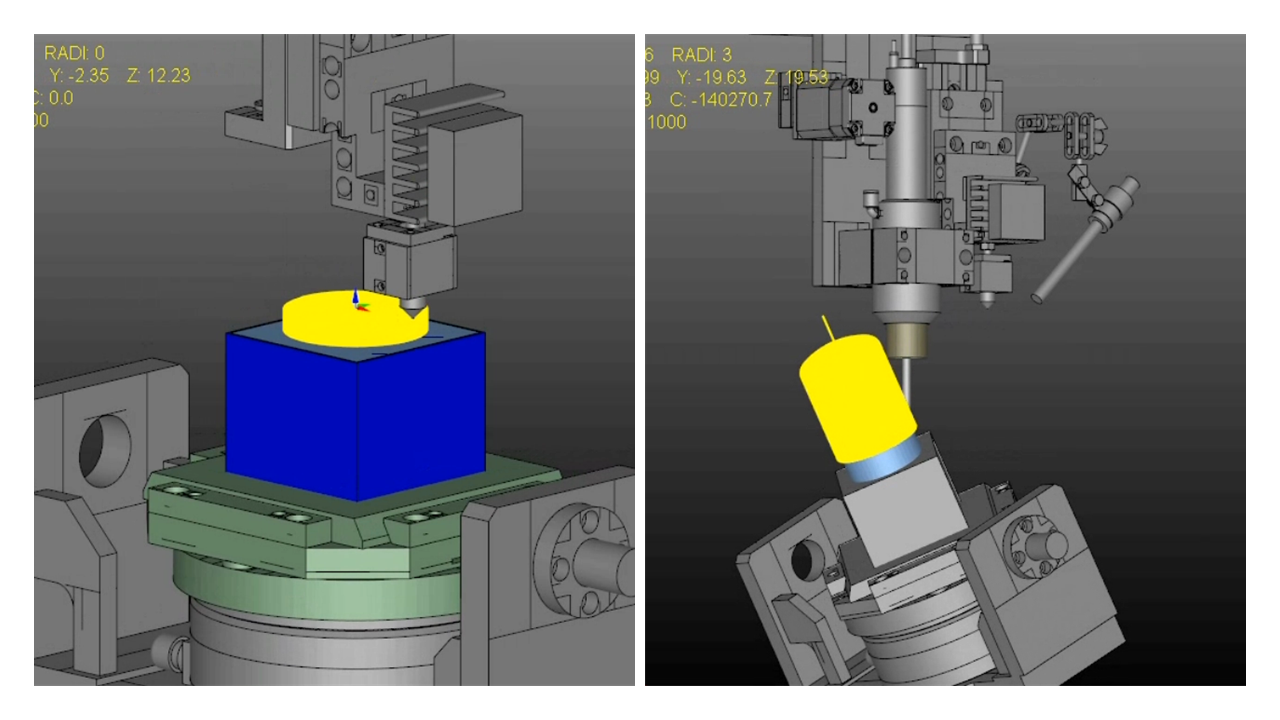

"CAM-TOOL AM" is a compound CAM system capable of simultaneous 5-axis control, which is equipped with a new machining mode to generate DED(Directed Energy Deposition)or MEX(Material Extrusion)stacked forming paths in CAM-TOOL. A new process design combining additive manufacturing (additional machining) and conventional cutting (removal processing) can be carried out in one system. The laminating process achieves the same operation as the conventional cutting process, enabling the operator to create data without any special operation from shape setting to pass output.

CAM-TOOL will contribute to the creation of new products through the fusion of advanced technologies with proven technologies cultivated in cutting.

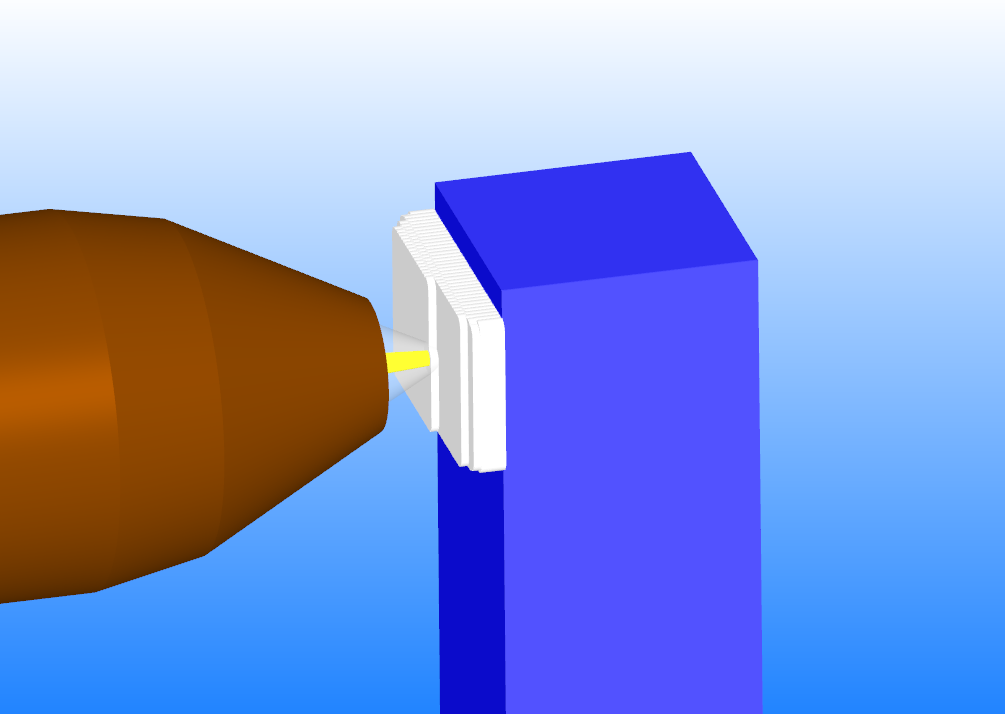

DED(Directed Energy Deposition)<

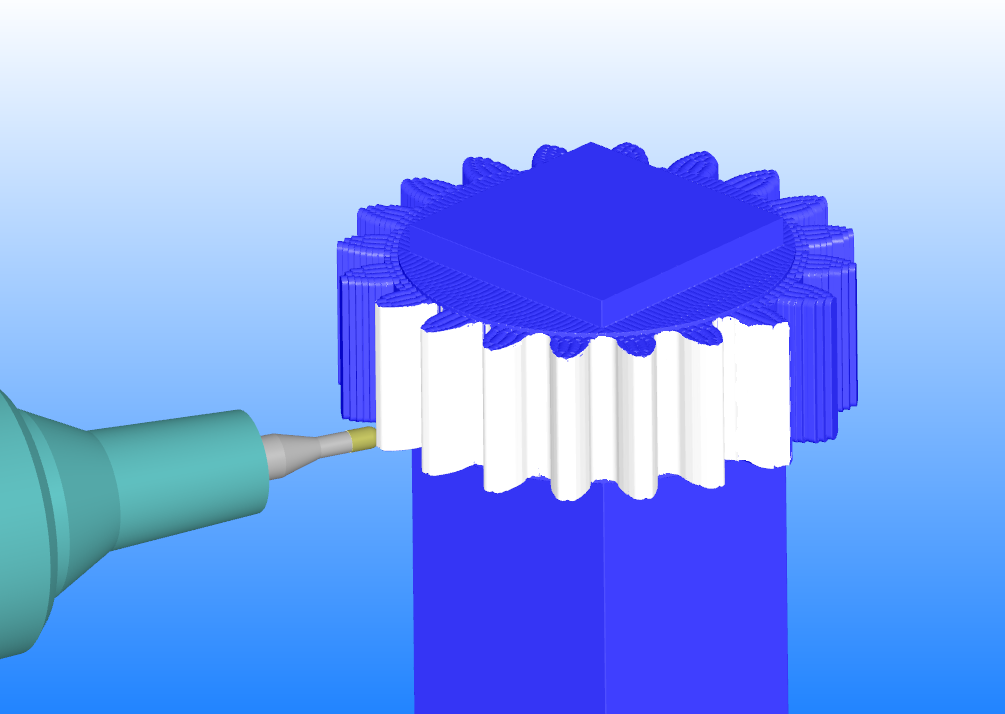

The DED method where metal powder is supplied to the laser irradiation position from the nozzle, then metal dissolves and solidifies. MEX(Material Extrusion)

The MEX method where melted resin is ejected from the nozzle, then resin is deposited and solidifies.

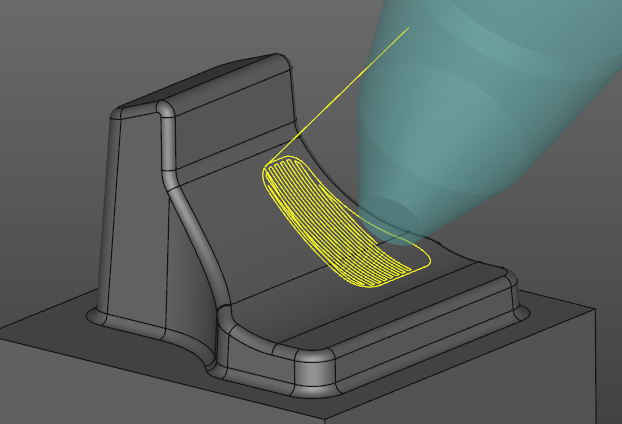

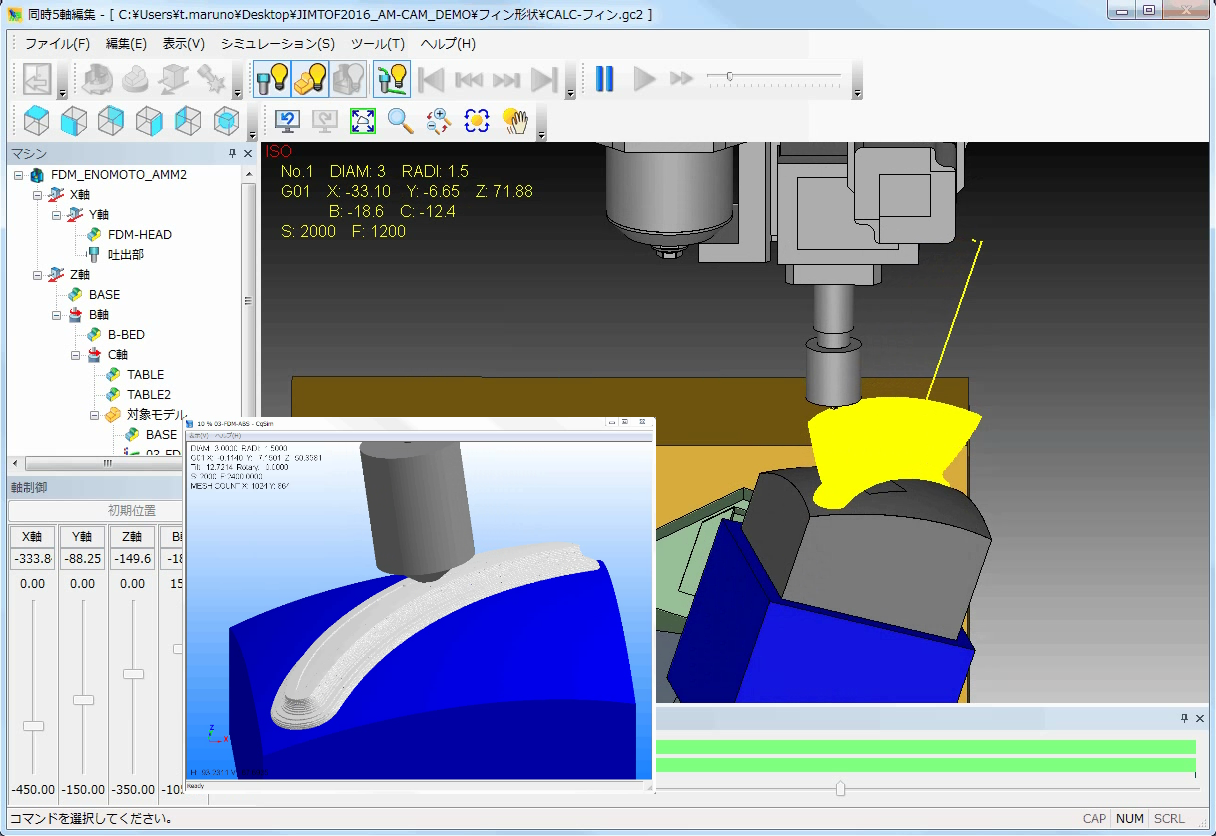

1. AM(3+2 Axis)

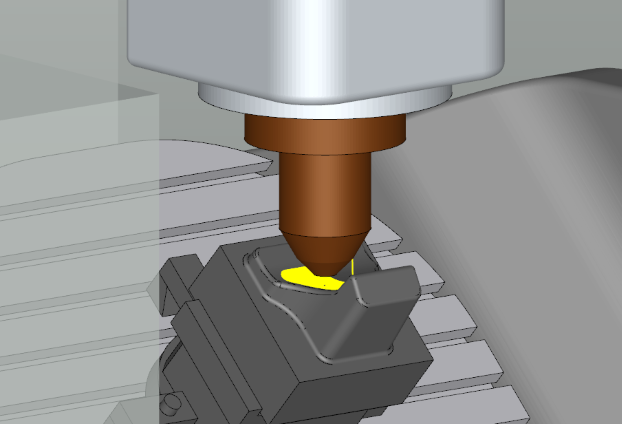

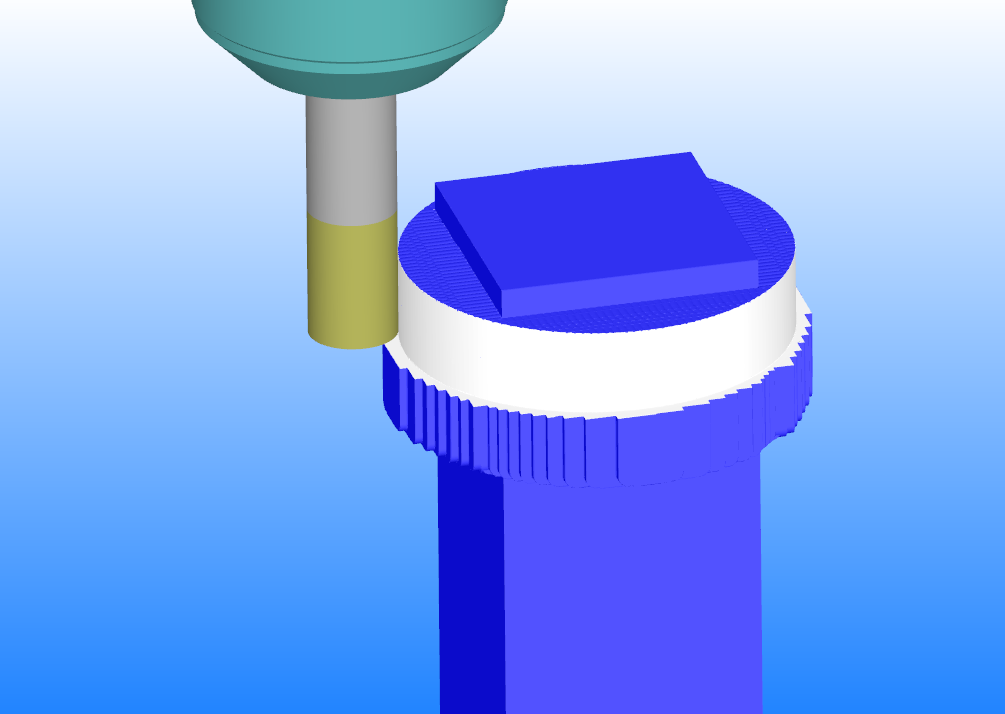

2. Milling(3D)

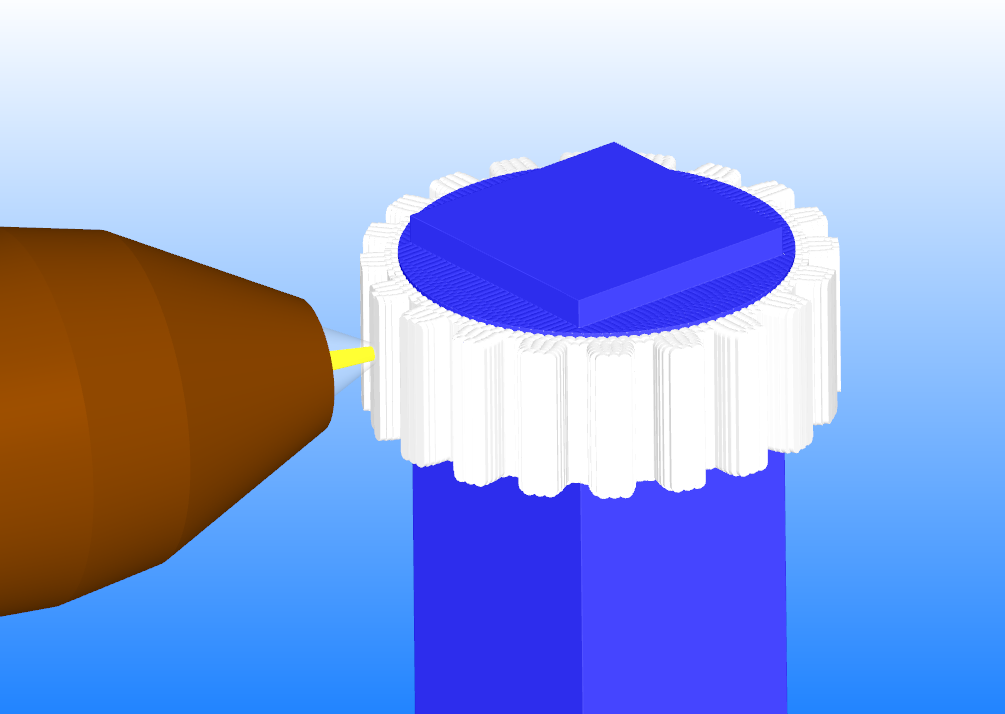

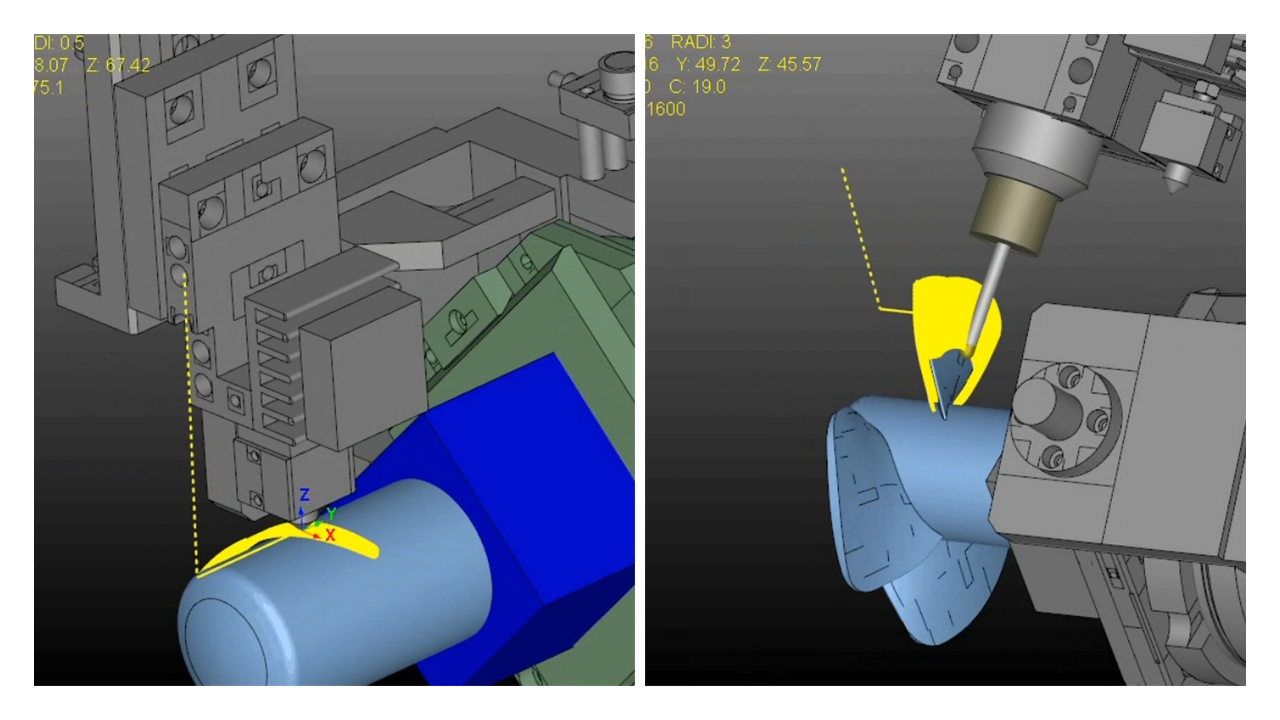

3. AM(Simultaneous 5-axis)

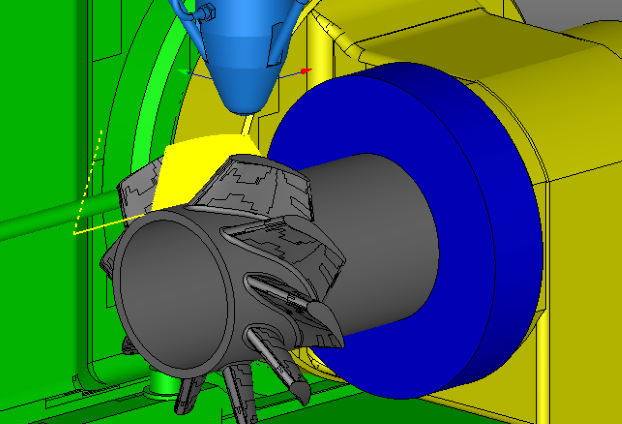

4. Milling(Simultaneous 5-axis)

It does not require STL data or slice data, and directly generates modeling passes and machining passes after modeling from 3D CAD data.

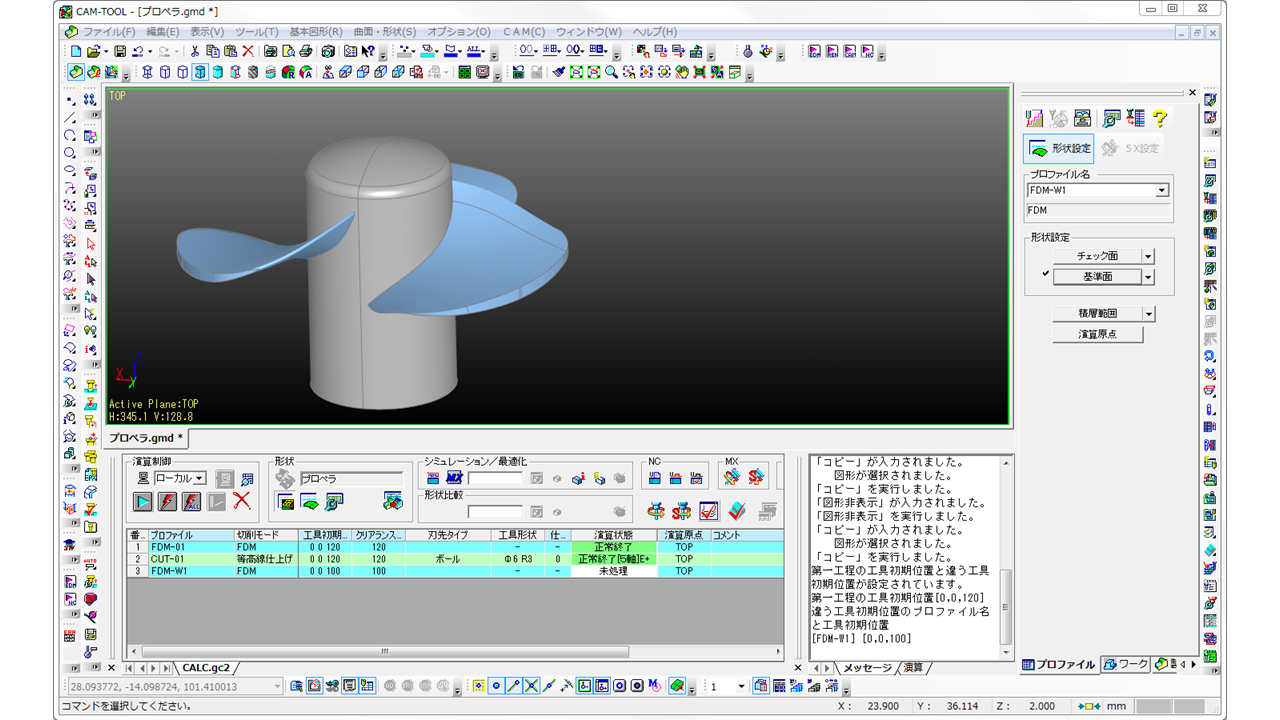

1. Model decomposition(Hub/Wing)

2. AM/3D(Hub) | 3. Milling/5-Axis(Hub)

4. AM/5-Axis(Wing) | 5. Milling/5-Axis(Wing)

CAM-TOOL AM(DED) has been developed by C&G SYSTEMS INC. adopting the results of the technology development project contracted to Technology Research Association for Future Additive Manufacturing (TRAFAM) by New Energy and Industrial Development Organization, a National Research and Development Agency.

Product Inquiry

Contact us

© Copyright 2010- C&G SYSTEMS INC. All Rights Reserved.