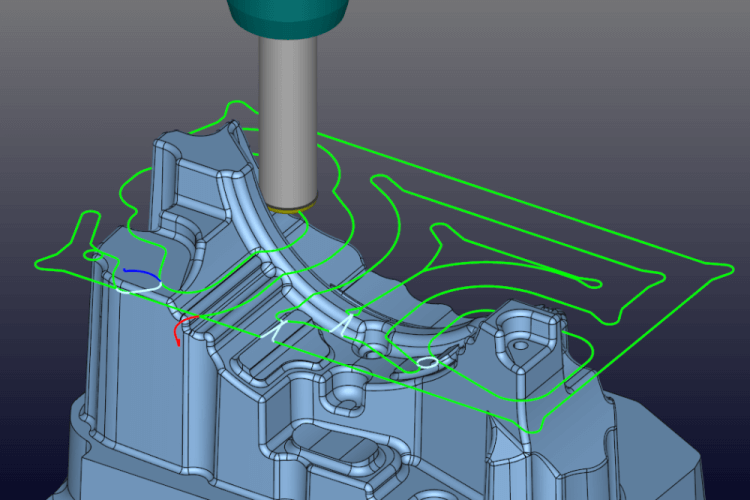

SYSTEM MODULE 3D Milling / 2.5D Milling / HOLE

3D CAM Module

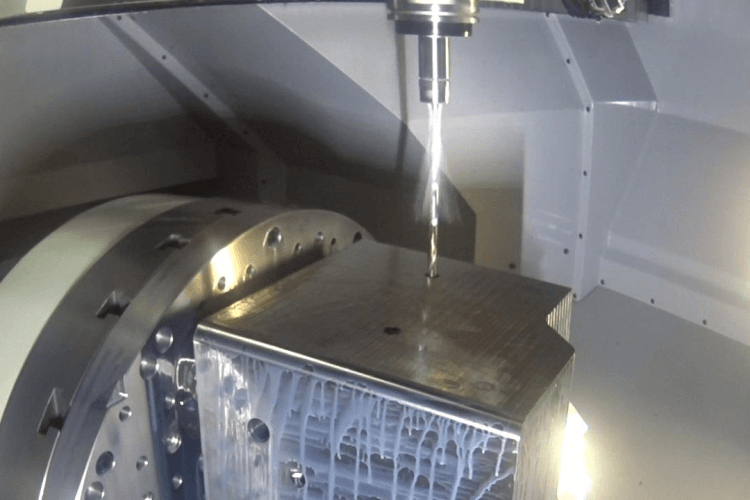

Suppresses Tool load fluctuation even in High speed direct cutting on high hardness steel.

CAM-TOOL provides powerful toolpath portfolio to satisfy the advanced milling professionals.

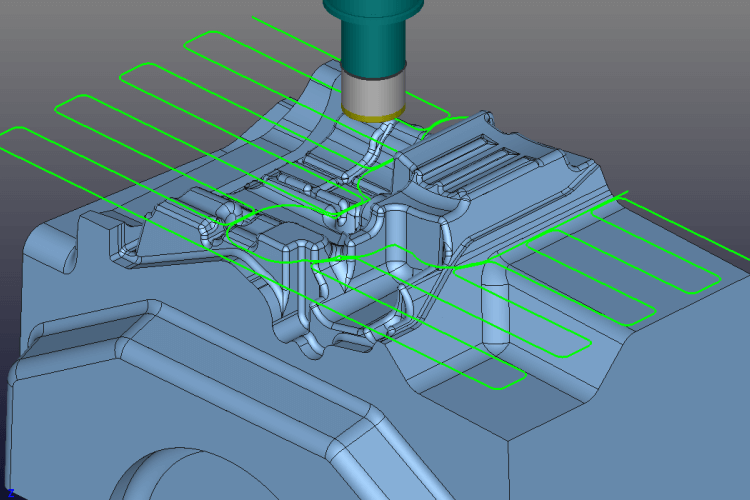

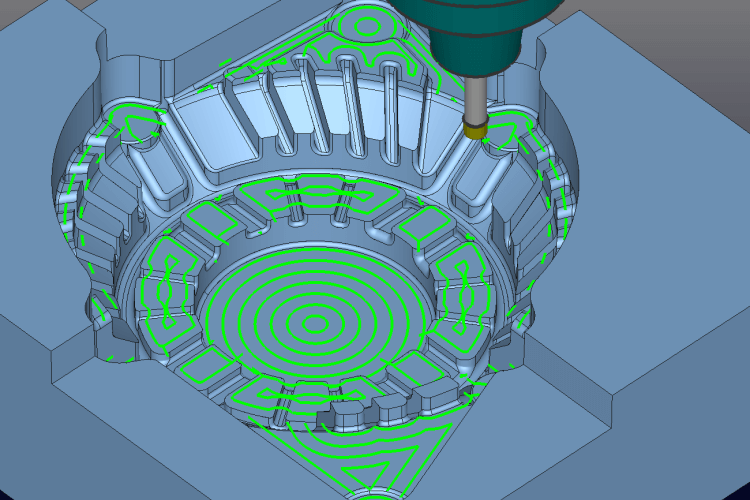

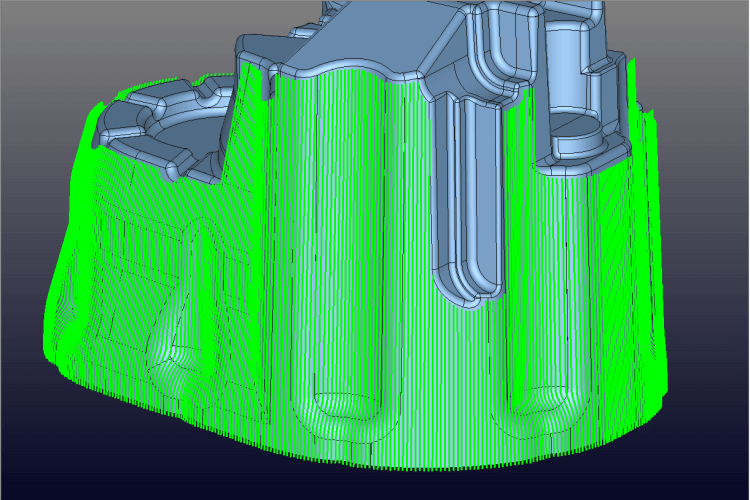

Z-level Rough Cutting with Multiple Tools

This cutting mode performs efficient Z-level offset roughing, recognizing user-defined work or stock model from the previous process. Along with "Arc processing" and "Z step down for gentle slope", the combined radius tool also can be used. Tool-paths recognizing the combined radius and the accurate material stock are generated, which enabels to achieve the efficient machining with constant stock remains.

Z-level Re-machining

This is a function that performs Z-level offset cutting for the remainders detected by specifying the tool of the previous process. Ball end mill, radius end mill and flat end mill tools are available.

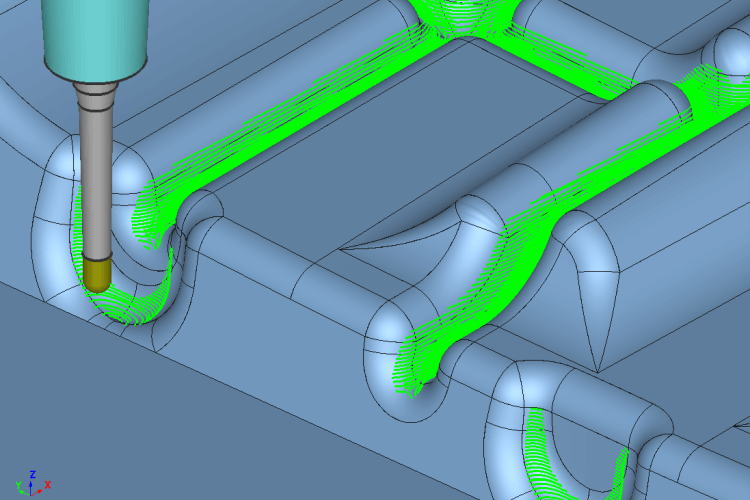

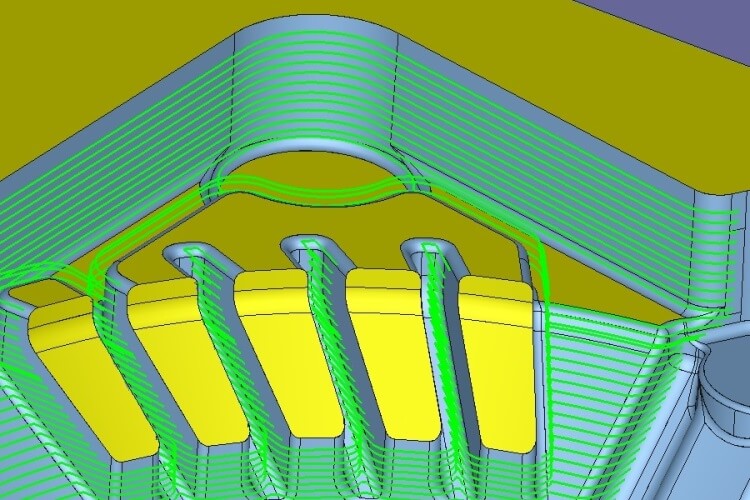

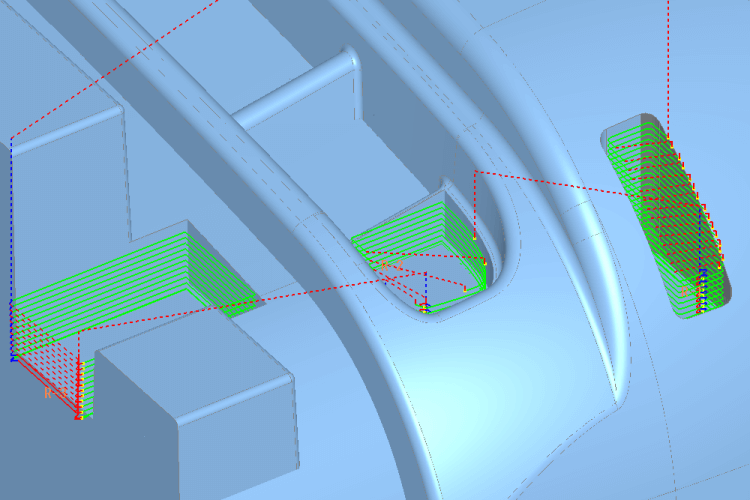

Corner Processing (Polygon)

This mode outputs "Along surface offset path" and "Contour line offset path" in the remainder regions such as groove parts or ridgeline parts where the tool of the previous process could not access. The type of the output cutter paths differs depending on the angle of inclination in the remainder region. "Along surface offset path" is output in a gently sloping area and "Contour line offset path" is output in a steeply sloping area.

Z-level Scanning-line Rough Cutting

This cutting strategy creates Z-level & bidirectional tool paths for roughing. Scanning-line bidirectional cutting reduces the connecting move, which makes it possible to shorten the cutting time. Moreover, both core and cavity shapes can be cut, and for a composite shape, the system automatically detects cutting areas and outputs cutter paths.

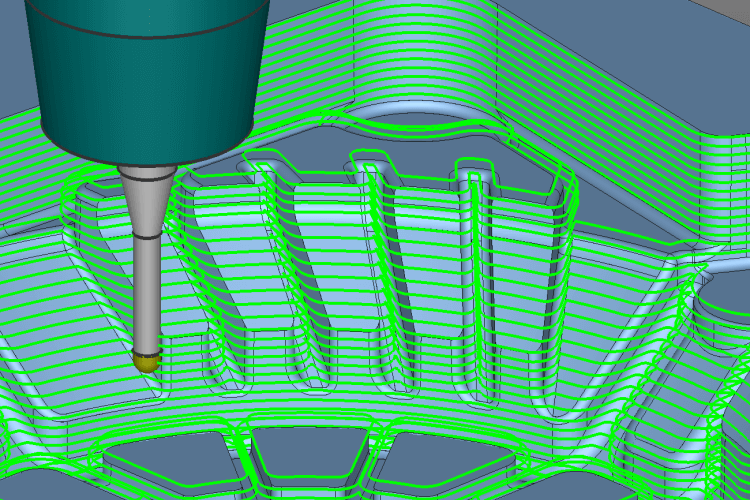

Z-level High Efficiency Rough Cutting (Climb-up Roughing)

High-performance roughing with constant cutting-load can be achieved by using blade length of the tool efficiently. After roughing by specified Z pitch, climb-up roughing by smaller Z pitch is processed with variable XY step-over considering cutting-load.

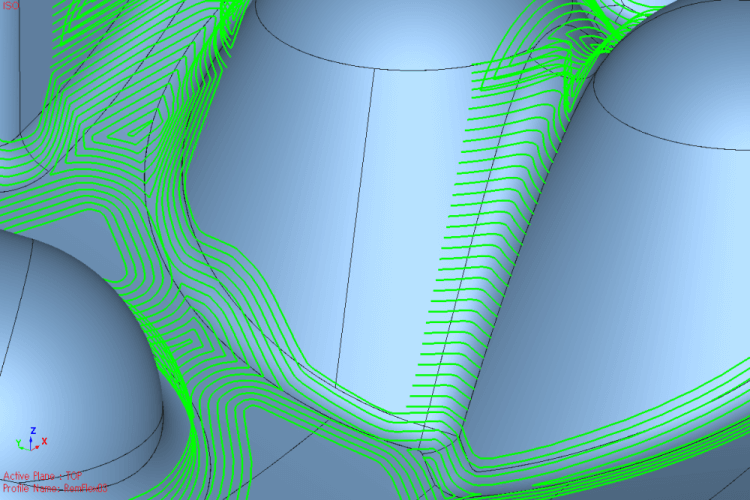

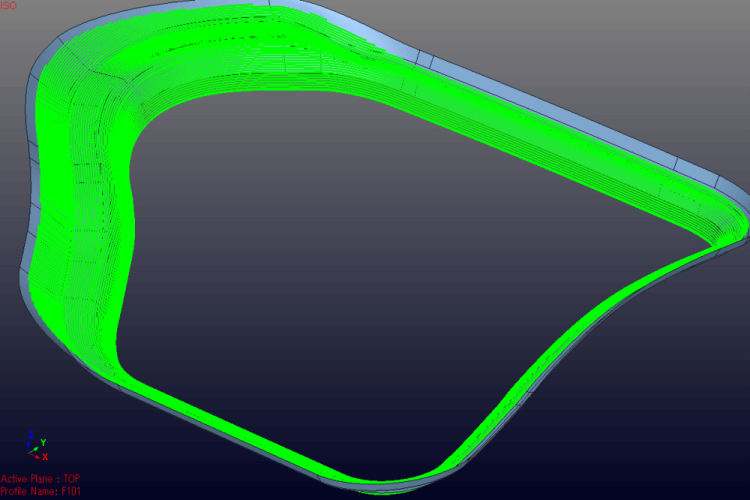

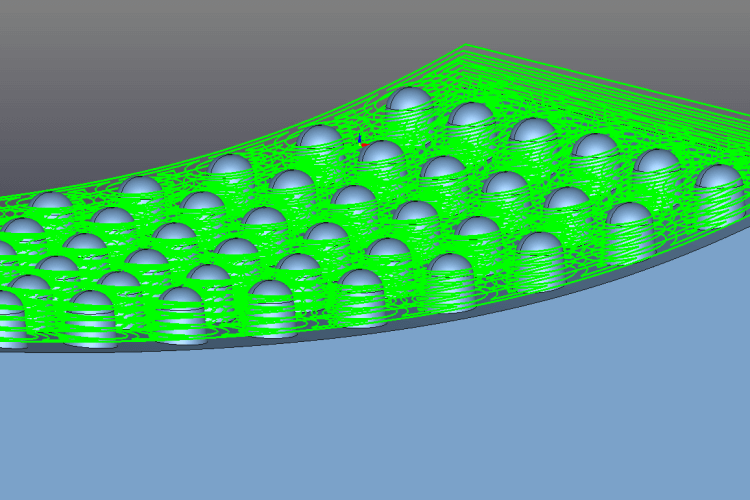

Curve Control Along Surface

This mode cuts along 3 dimensional surfaces within the closed area enclosed by contours. U/V of surfaces don't affect the cutter paths. Air-cut can be reduced especially for a large metal mold.

3D Offset Cutting

This is a finishing mode that outputs offset cutter paths along surfaces with a constant step. This mode outputs cutter paths for the entire shape in the specified area with a constant step and leaves uniform stock.

Base surface modes

“Base surface modes” are new powerful cutting modes to create tool path on specified base surface.It achieves extreme quality surface finish by the surface calculation characterizing CAM-TOOL.In can eliminate retracts substantially, so it will also prevents the deterioration of surface finishing, and furthermore, it reduces cutting time!

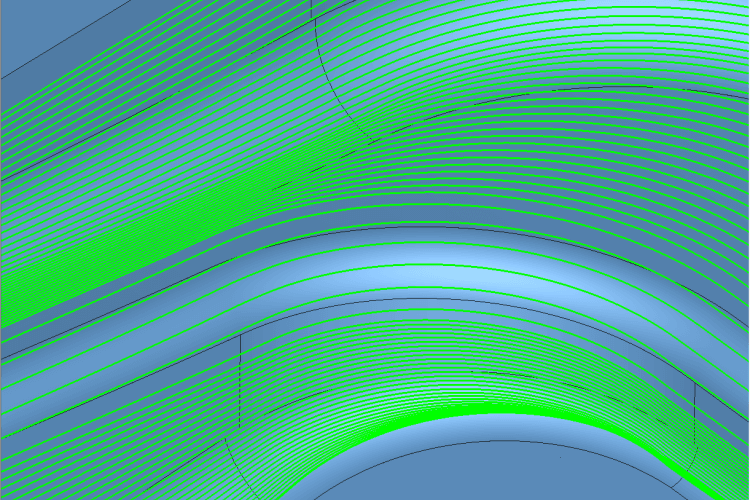

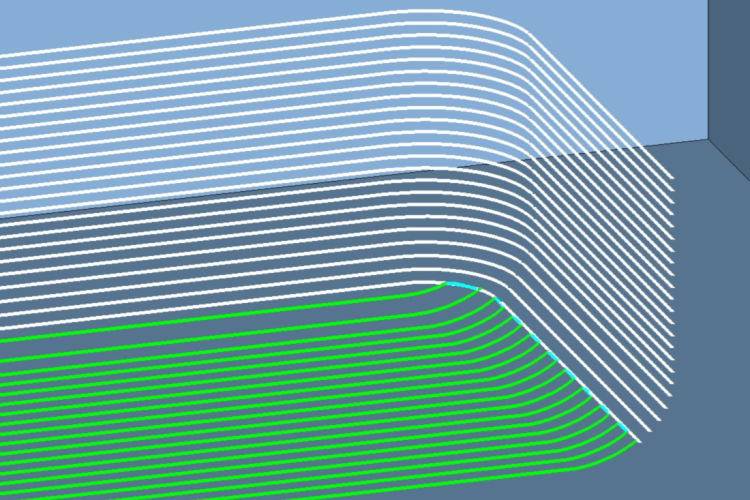

Z-level Finishing

Performing Z-level cutting, which uses climb cutting, suitable for high-speed and high-precision machining, enables a high-quality surface finish required for mold manufacturing. It is also possible to cut near-horizontal areas by adding "Offset cutting", or by using "Low Lying Processing" or "Scanning-Line area" together. With a variety of useful parameters and functions like "Spiral cutting", Z-level Finishing has been widely used from the semi-finishing process to the finishing process.

Horizontal Area Cutting

Horizontal areas of the specified shape are automatically detected and machined. The climbing cut is always performed and cutter paths traveling around (contour line) are output.

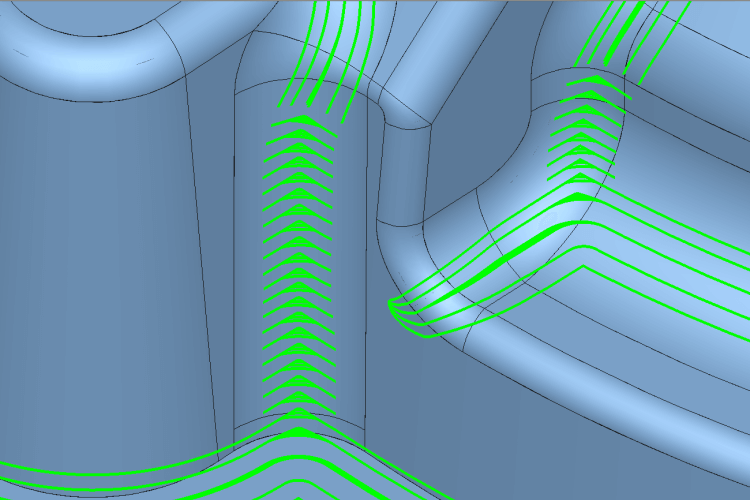

Re-machining

This is a function for re-processing the regions that were left uncut, using a smaller tool. Based on the radius of the previous tool, remainder regions are automatically detected and cutter paths are generated for those regions only. Cutting of remainder regions can be performed along ridgelines or perpendicularly to ridgelines, depending on the angle of the ridgeline.

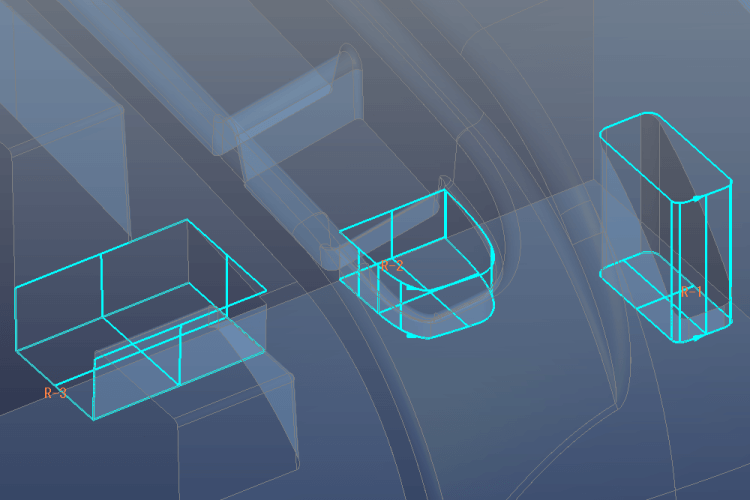

Box Cycle Cutting

Considering slide direction of the mold, this cutting mode creates vertical directional tool path on particular walls. Remaining cusps crossed slide direction can be reduced by vertical milling, which enables to shorten polishing time. Improving of dimensional accuracy also can be expected by repressing of cutting tool incline.

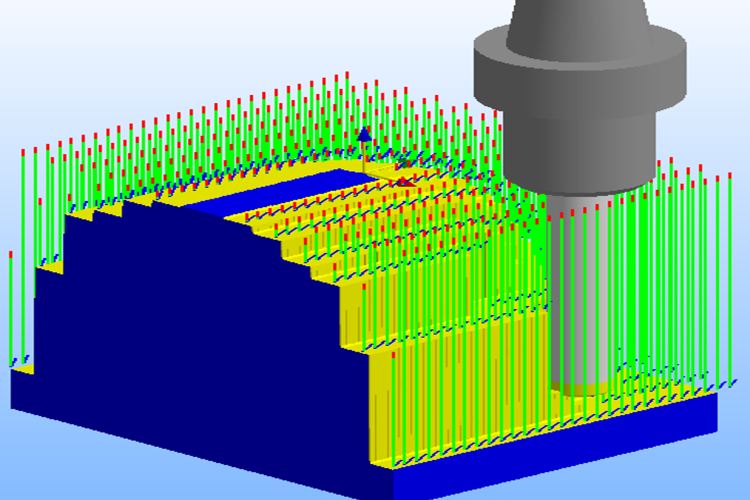

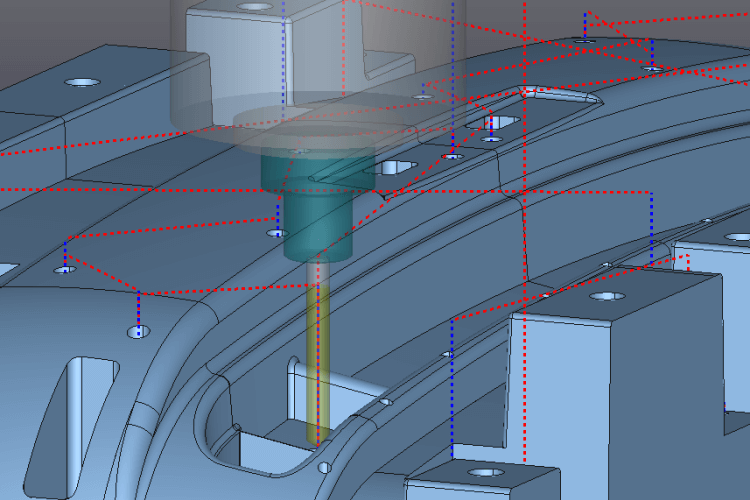

Plunge Cutting NEW

The tool repeatedly cuts using the bottom edge of the tool through a series of thrust movements in the axial direction of the tool at a fixed pitch. Tool deflection due to bending load during cutting is hardly generated, and heavy cutting is easily performed, making it effective for roughing deep and large workpieces. In addition to improved operability, stock calculation, area instruction, load control, and positioning are also supported to expand the variation of roughing methods. (Available from Ver. 18.1)

Various functions to assist milling mode

Corner R Processing

Reduces tool load by inserting fillet to corner of the shape. It also achieves machining time reductions by smooth movement.

Face not to machine / Different stock surfaces

"Surfaces avoiding to machine" or "Surfaces with different stock from others" can be specified at "Shape setting". It allows more efficient tool path for machining to be created easily.

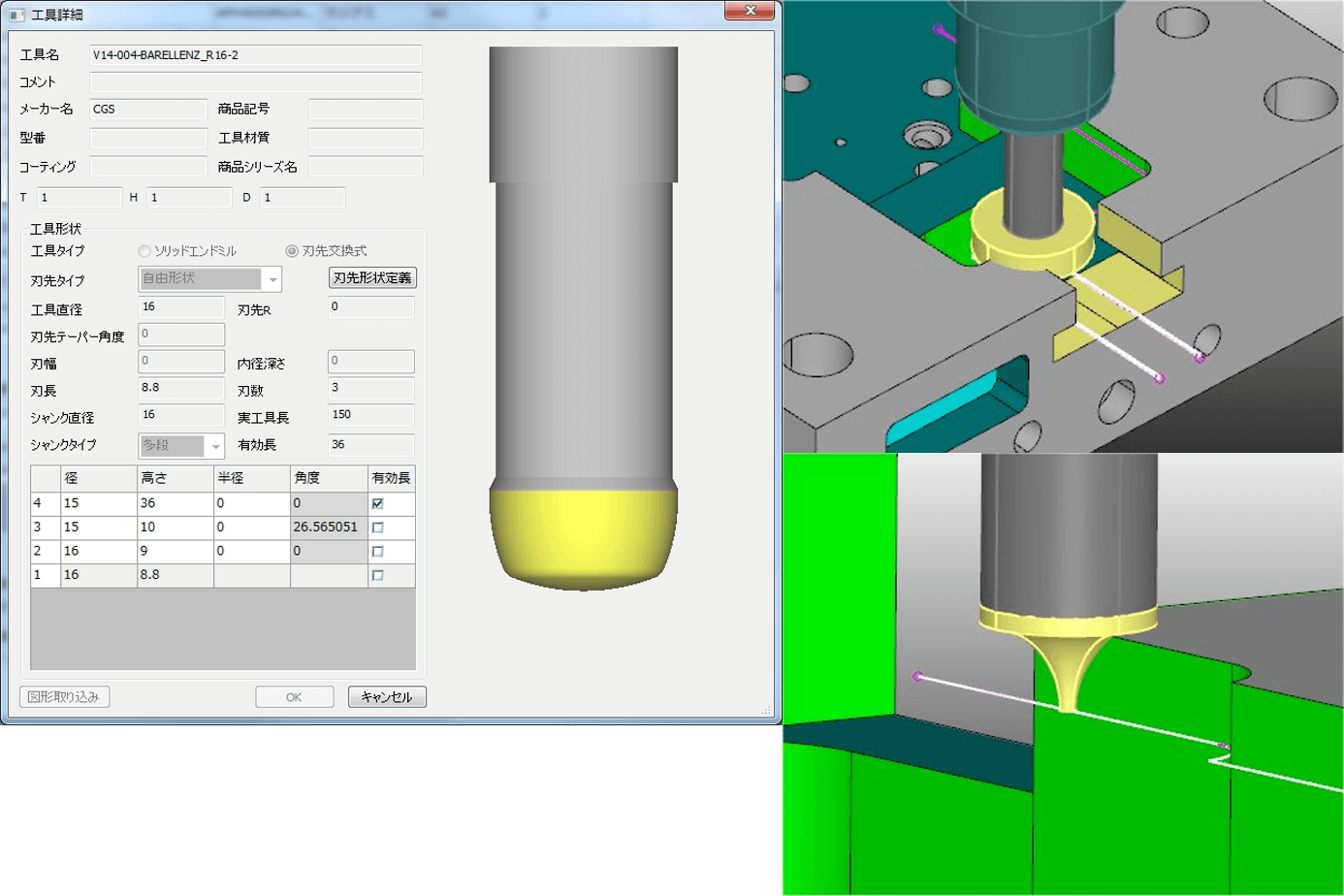

Barrel cutter support

Able to generate toolpaths with unique silhouette cutters like barrel, lens, oval cutters. It supports 5axis machining, intereference check and cutting simulation.

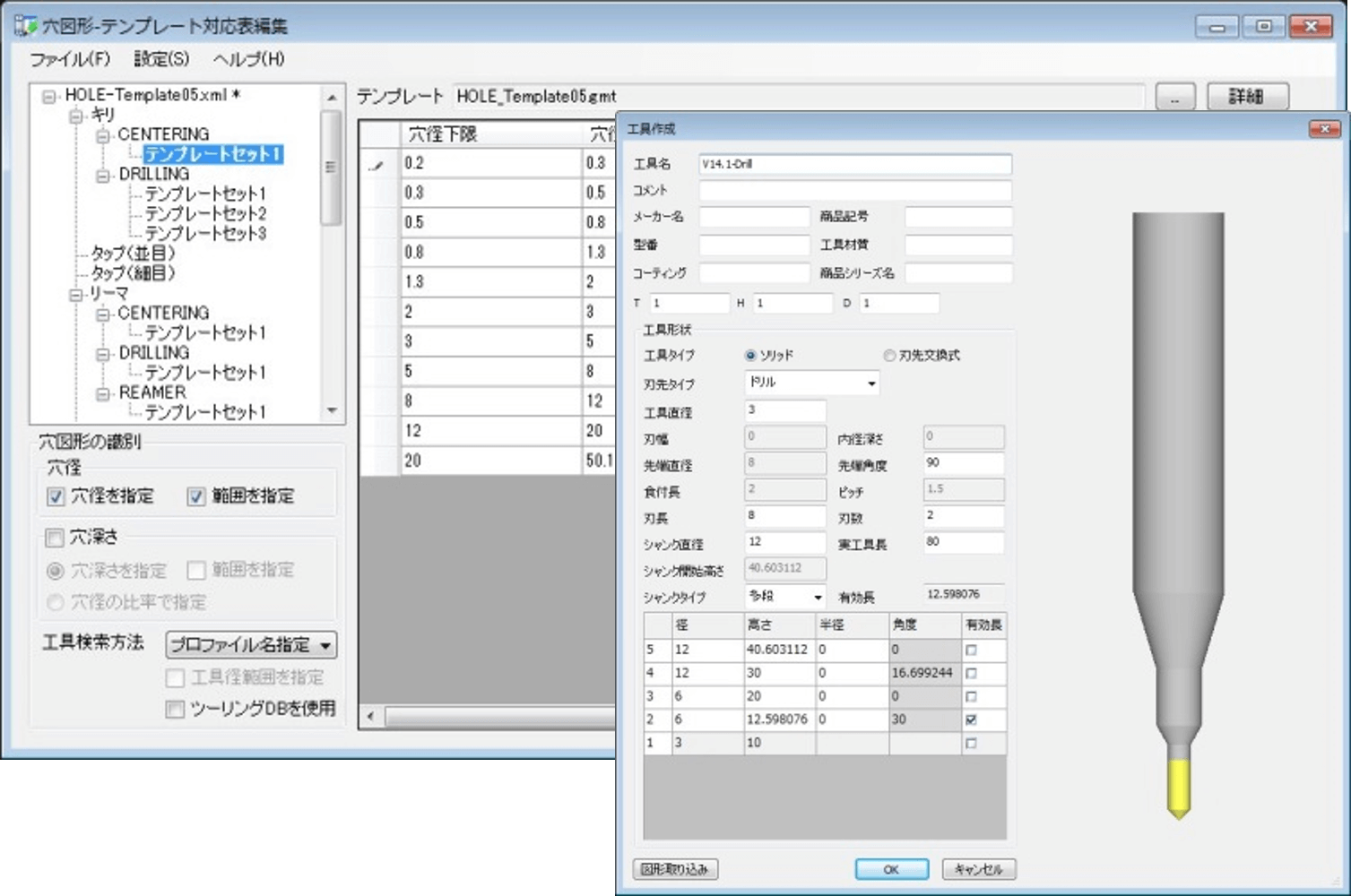

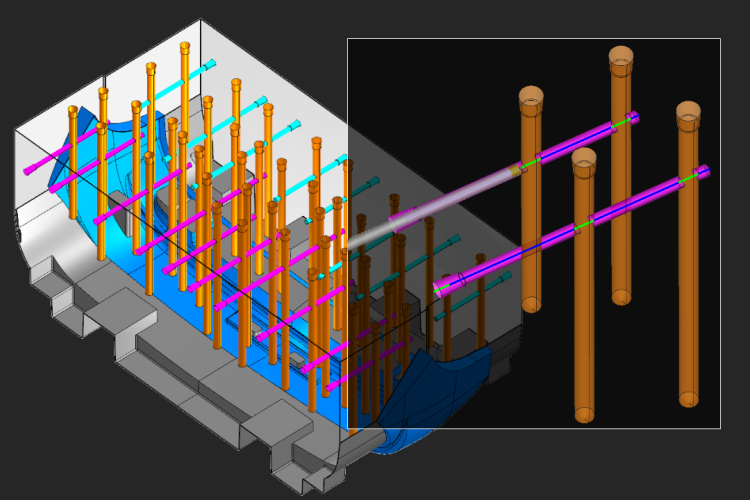

HOLE Module

Operation integrated into 3D CAM achieves efficient and safe machining.

Hole feature can be defined by Entity, based not only on Point Circle but Arc/Curve/Surface. Hole processes are controlled on the "Calculation Process List" the same as 2.5D/3D. This provides safe Hole cutting because of interference checking for the remaining stock model after machining. It is also possible to improve efficiency of Hole cutting thanks to optimized CL.

2.5D CAM Module

Recognize wire frames and curved surfaces and create safe and efficient processing data

It’s possible to set multiple sections at the contour of wire frame and define a pocket and an island shape. Section and plane parts whitch are machined by 2-axis/2.5-axis in the surface model are detected and cutter paths are generated.

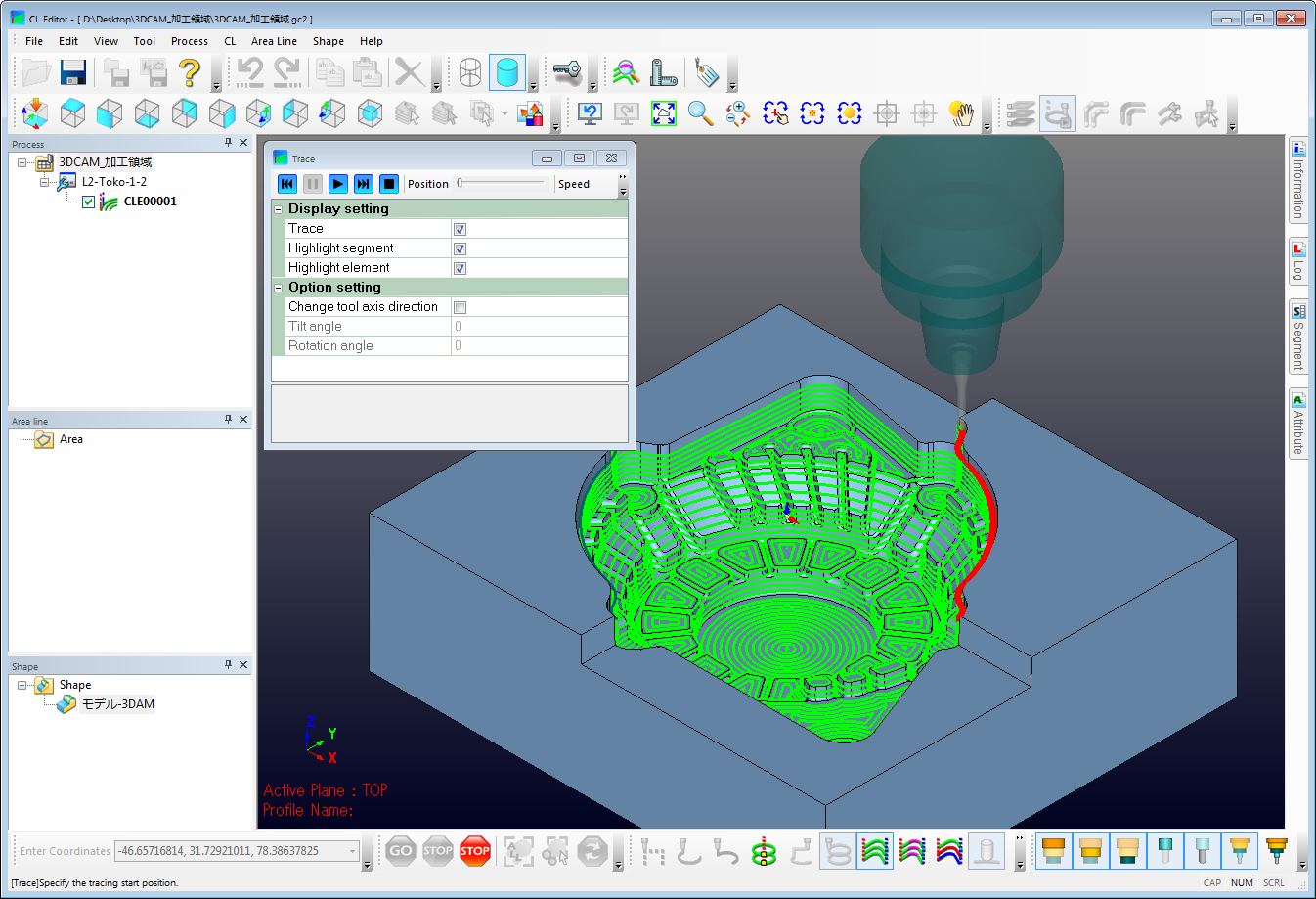

CL Editor Module

Advanced CL path editing utilizing know-how

With a User Friendly GUI, it's possible to edit and check various types of CL.

- [ Main Function ]

- CL information / Trace / Move / Copy

- Delete CL partially

- Modify Approach / Change Approach Position etc.

CAM Function(Common)

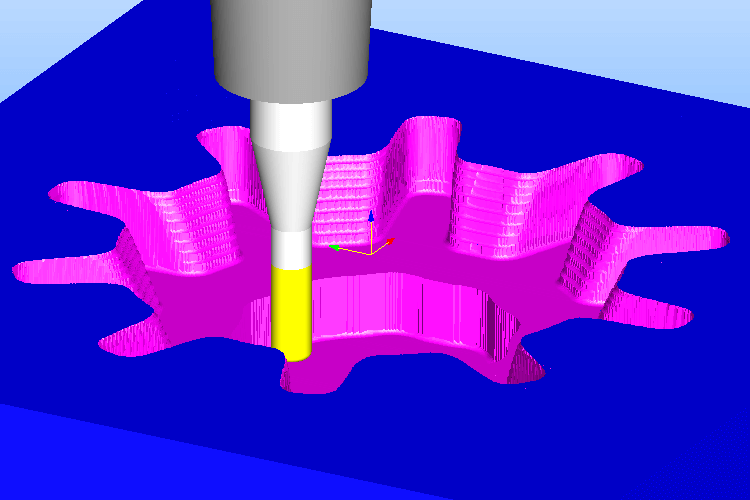

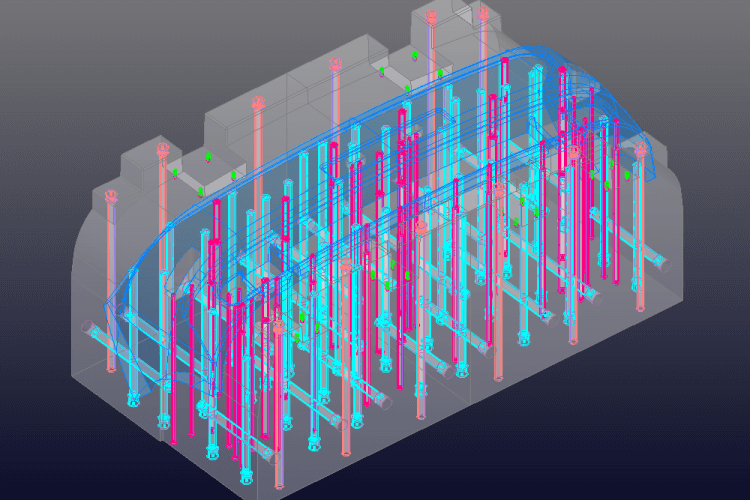

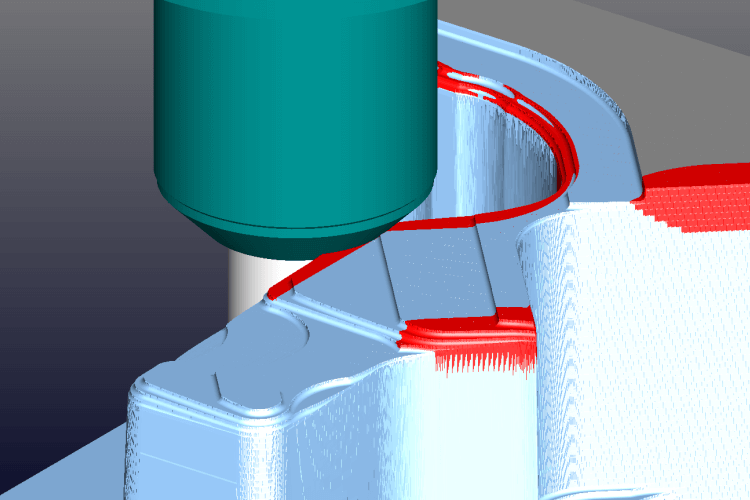

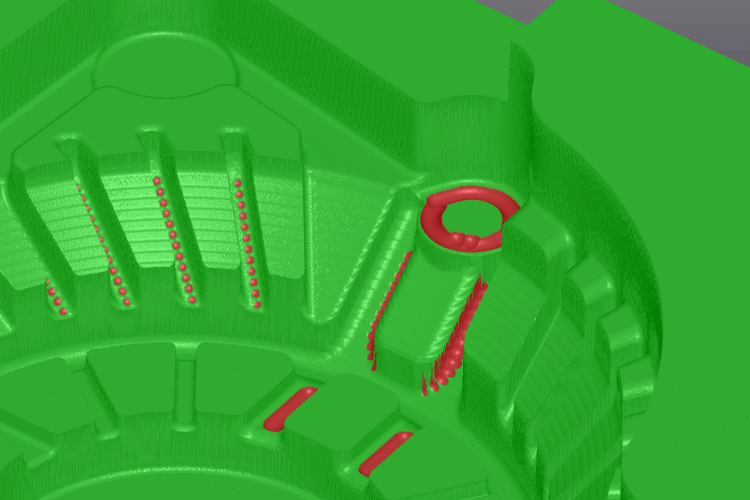

Optimization/Cutting Animation

Optimization can be performed with Tool registered in DB and simulates the milling to show the condition of the work after machining and to also check the interference point.It's also possible to generate tool path more efficiently and safely because of "Delete air-cut", "Auto clearance", "Variable feed rate", etc.It is now possible to see the animated machining process after optimization.

USER INTERFACE(Common)

Intuitive interface to save labor

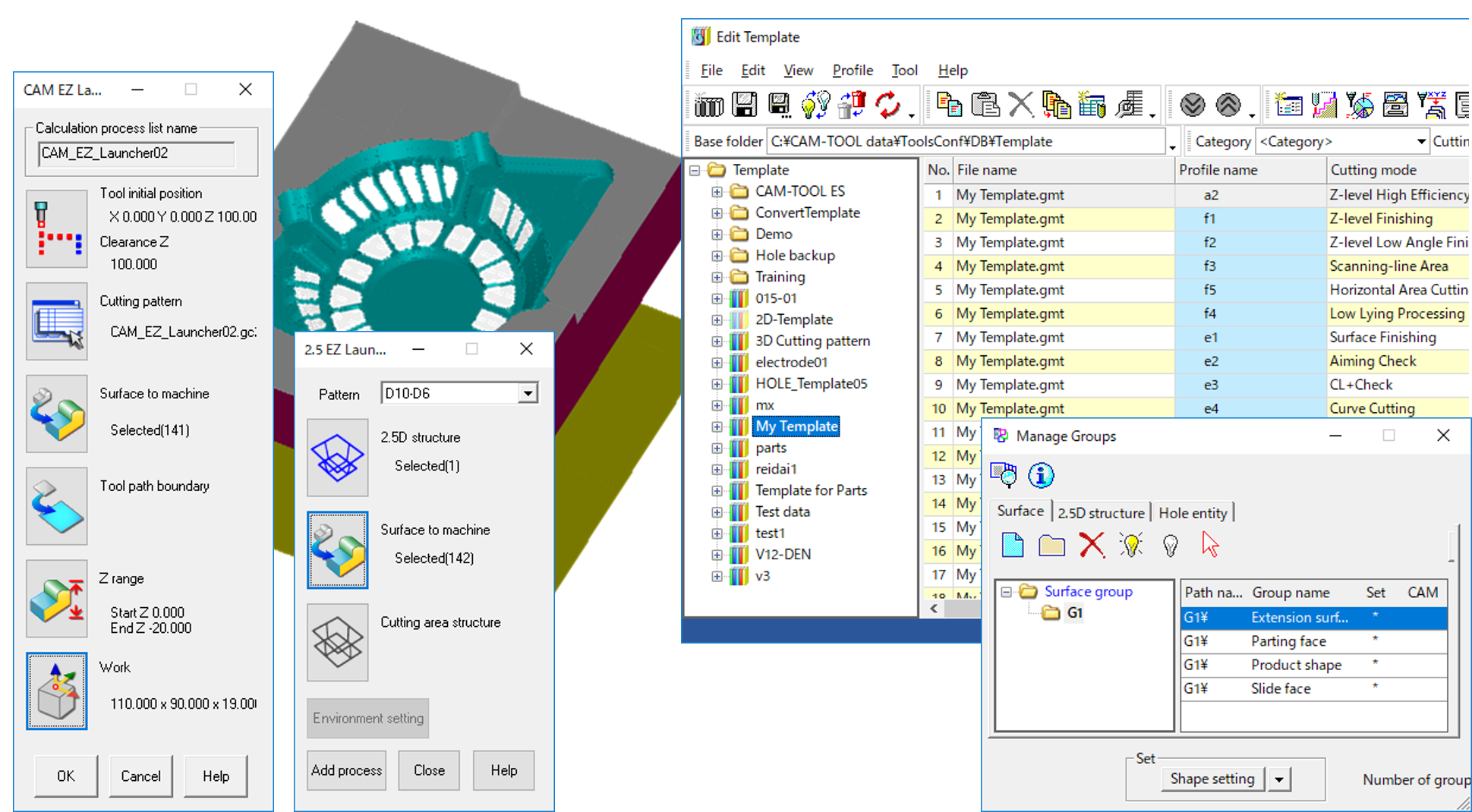

Surface Group/Template

Registering each machining surfaces (ex. PL Surface, Product Surface) as specified groups makes the shape setting operation for CAM easier. It also automatically set shapes at once for plural machining processes when using "Template".

CAM EZ Launcher

"CAM EZ Launcher" accelerates to create machining processes, and contributes to avoid human errors, achieving simplification and standardization of CAM operation. For 2.5D machining, "2.5 EZ Launcher" is also available.

Ribbon Menu

Ribbon menu similar to Microsoft Office is newly supported. Working efficiency can be improved by customizing it to display frequently-used commands in each working area.

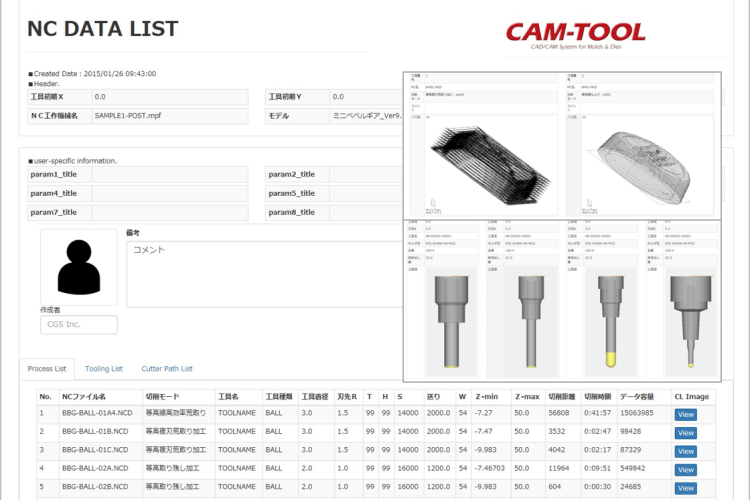

Process Sheet

NC Process Sheet can be output automatically when NC data is created. It is output as EXCEL format or WEB format.

Product Inquiry

Contact us