CASE STUDY

Case Study

Please use the document request form to download the product catalog (PDF file).

Document request form is here.

Zing Chuan Technology CO., LTD

NEWPioneers at the Forefront of Taiwan’s Mold Industry

Shaping the Future with CAM-TOOL and Additive Manufacturing

Founded in 1986, Zing Chuan Technology CO., LTD. began as a mold manufacturer and has grown under the innovative leadership of its founder, Mr. Yeh Tseng-Sung. In 2003, the company added a plastic injection molding facility, followed by an assembly division in 2009, building a full one-stop production system from design to manufacturing and assembly. Its products are used in home appliances, medical devices, and automotive parts. In recent years, Zing Chuan has also developed and sold its own brand of smartphone cases—continuing to challenge itself with new value creation.

LIY CHENG PRECISION CO., LTD.

Fusion of Craftsmanship and Cutting-Edge Technology! LIY CHENG PRECISION and CAM-TOOL Pioneer the World of Precision Mold Making!!

Founded in 2012 in Taichung, Taiwan, LIY CHENG PRECISION CO., LTD. (hereinafter referred to as "LIY CHENG PRECISION") provides one-stop services for the design, development, manufacturing, and measurement of various plastic molds by fusing state-of-the-art technology with masterful craftsmanship, all while pursuing continuous improvement. …

Nagoya Precision Mold Co., Ltd.

As expected, CAM TOOL can also be applied to 5 axis machining.

Since its establishment back in 1975, our client, Nagoya Precision Mold Co., Ltd., has been engaged in the beginning to end processes from the designing to the manufacturing of molds for plastic injection molding, and has been expanding its business globally. …

SANKO LITE INDUSTRIES CO., LTD.

Improve bottlenecks by introduction of “Surface Plus”, reducing man hours for mold model editing down by 40%!!

Our client, SANKO LITE INDUSTRIES CO., LTD., designs and manufactures the molds, and then processes, paints and assembles housing parts of communication devices, such as mobile phones and PHS phones, in addition to automobile components, plastic tableware and many others. …

SHOWA MOLD & ENGINEERING CO., Ltd

Only one year after the introduction of CAM-TOOL, Showa was able to reduce man-hours significantly.

SHOWA MOLD & ENGINEERING is based in Tokushima, founded in 1937 as a manufacturer of precision equipment,They’re designing and manufacturing the molds & dies of large plastic parts, including interior parts such as door panels and instrument panel of the car, and exterior parts such as bumper and extension headlamps, OA equipment, the main case frame of office equipment. …

Case Study

Please use the document request form to download the product catalog (PDF file).

Document request form is here.

OTA Co., Ltd.

Reduced lead time for press design by moving away from combined system use!

OTA Co., Ltd. was established in Matsumoto, Nagano in 1971. This company excels at metal stamping of difficult-to-machine materials, and also designs and manufactures precision progressive dies. The metal press parts designed are gaskets and brackets for automobiles. Today, we interviewed Mr. Shugo Ota (President), Mr. Takayuki Kato (Design Manager), and Mr. Junichi Kato (Chief Engineer). …

Muramoto Industry Co., Ltd.

Significantly reduce the required man-hours in intermediate modeling process for drawing press die by utilizing newly developed surface functions!!

Muramoto Industry Co., Ltd. has several production facilities in Japan and overseas, dealing with not only a wide variety of die/mold manufacturing, such as automotive parts, home appliances and information appliances, but also product assembly as well. …

SANSHIN HIGH TECHNOLOGY (THAILAND) LTD.

Sanshin High Technology, a press die maker, strengthens its die division and improves its in-house production rate!

Sanshin High Technology (Thailand) (hereinafter referred to as Sanshin), based in Ayutthaya, is a metal parts processor with presses ranging from 45 to 300 tons, and manufactures press dies and supports mass production. The company was established in Thailand in 1996, and this year (2023) will mark its 27th year. The production of dies was primarily outsourced, but in light of the intensifying price competition, it became necessary to review the situation in order to enhance the in-house production rate.

HORIUCHI TECHNOLOGY(THAILAND)CO.,LTD.

One-Year Plan to Localize and Streamline Press Die Design!

Horiuchi Technology (Thailand), a Thai subsidiary of Horiuchi Technology Co., Ltd. (Headquarters: Iwata City, Shizuoka Prefecture), is a manufacturer of 3D machining, designing/manufacturing of press dies, and prototype production as in Japan. Ever since their founding in 1960, they have consistently worked hard to provide their customers with high-precision, short-term delivery, and low-cost dies. They entered the Thai market in 2010 and have been designing and manufacturing high-precision press dies of Japanese quality at their own factory in the Amata City Rayong Industrial Estate.

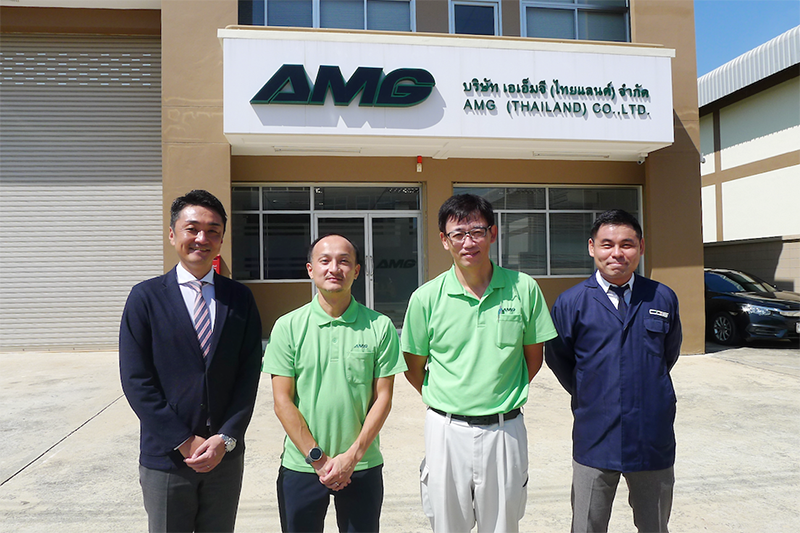

AMG(THAILAND)CO.,LTD.

We support the production of ultra-precision mold/die from AMG, which boasts micron-level accuracy!

AMG Co., Ltd., located in Ishikawa Prefecture in Japan, manufactures precision mold/die parts and precision plastic molds/dies, sells precision parts, and manufactures and sells precision plastic parts. With Mold/die and precision plastic parts with craftsmanship, they support precise and high-quality “manufacturing” of Made-in-Japan. The company expanded into Thailand in 2018, established AMG (THAILAND) CO., LTD. and manufactures precision mold/die parts used in Japan in Thailand. AMG Thailand's Hidemichi Araie is one of Japan's top precision mold/die designers. In addition, Kenji Yamada of the company is a leading expert in electrode design and manufacturing for die-milling electric discharge machining.

Case Study

Please use the document request form to download the product catalog (PDF file).

Document request form is here.

OMRON Corporation | Electronic & Mechanical Component Business Company

Omron introduced CG PressDesign on year 2011 as design system of precision metal stamping, and going toward the 50% less of delivery time by fully 3D die design and optimize of die design process.

Omron is providing important equipments such as control equipment of FA and electric parts, health and medical equipment in to the world. And Electronic & mechanical Component Business Company (herewith OMRON EG) is design center of Mold & Die for OMRON group in the world, and they are designing press precision parts and injection mold precision parts for relay device, switch, connector parts. …

Forming Solutions Inc.

With the introduction of CG CAM-TOOL, the trial production period is shortened from 1 week to 3 days !!

They recognized a need for Thermoforming in the Minnesota area having spent fifteen years in the industry. They did thermoforming consulting/designing/prototyping/engineering services for both the heavy gauge and thin gauge vacuum forming industries and for many years had farmed out the actual mold machining and creation. …

Case Study

Please use the document request form to download the product catalog (PDF file).

Document request form is here.

SHINSEI KOGYO CO., LTD.

The SHINSEI KOGYO CO., LTD. style "Work Style Reform" through Order Management ~ To grow orders ~

Mr. Hiromitsu Hamano became the second-generation president of SHINSEI KOGYO CO., LTD. in 2012. The challenge at the time was to further develop the foundation established by the former president. In order to keep being told that "There is a great group that designers and manufacturer molds in Okayama." The Process Management System AIQ has been in operation since 2017 with the aim of breaking away from orders that rely on experience and intuition. …