SYSTEM MODULE Detail of Function

Flexible Manufacturing System

AIQ-MfgSemiAuto

Revolutionising die-sinking EDM through centralised management and automation to drive digital transformation

The Semi-Auto Version centralizes all die-sinking EDM data in a database, significantly increasing process transparency. By tagging electrodes and workpieces with QR codes, the system ensures rapid, accurate data access, eliminating human error and boosting productivity through semi-automation. This flexible and efficient approach is characterized by low initial investment and high returns. Furthermore, the resulting cost reduction drives digital transformation (DX) on your shop floor.

The Semi-Auto Version centralizes all die-sinking EDM data in a database, significantly increasing process transparency. By tagging electrodes and workpieces with QR codes, the system ensures rapid, accurate data access, eliminating human error and boosting productivity through semi-automation. This flexible and efficient approach is characterized by low initial investment and high returns. Furthermore, the resulting cost reduction drives digital transformation (DX) on your shop floor.

Equipment selection

Chuck List

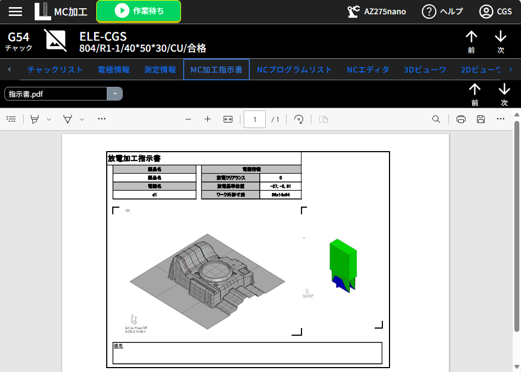

Drawing view

3D Model View

Processing Instructions

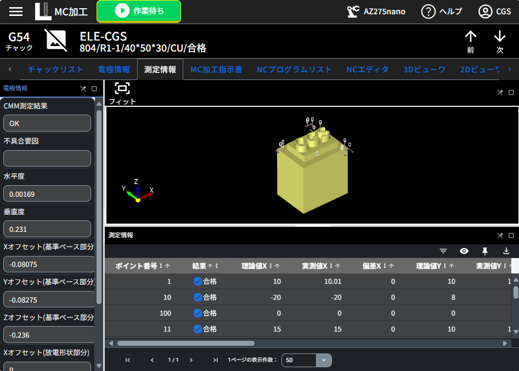

Measurement Information

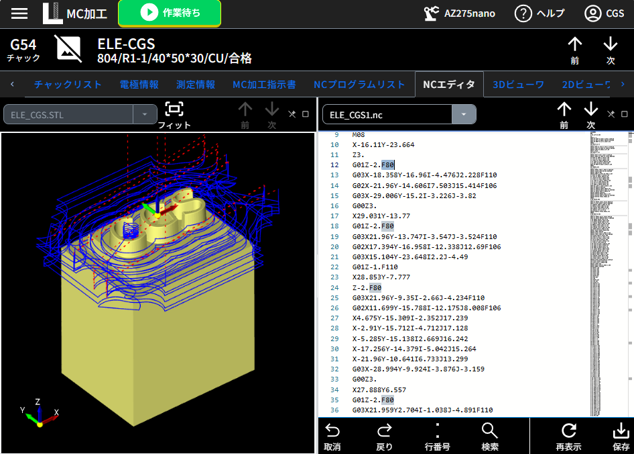

NC Editor

AIQ-MfgFullAuto

Next-generation full automation of electrode machining — Simultaneously achieving productivity and labour-saving

The Full-Auto Version is an integrated solution that fully automates the entire electrode machining process. It seamlessly links MC processing, CMM measurement, and EDM, combined with Autonomous Mobile Robot (AMR) for electrode and workpiece transport. This creates a completely unmanned line, eliminating manual intervention across machining, measuring, discharging, and material handling. This system is a crucial step toward realizing your Smart Factory vision, ensuring stable production, labor saving, and major gains in productivity, utilization, and setup time reduction. (Note: The Full-Auto Version is currently under development for commercial release in 2026.)

The Full-Auto Version is an integrated solution that fully automates the entire electrode machining process. It seamlessly links MC processing, CMM measurement, and EDM, combined with Autonomous Mobile Robot (AMR) for electrode and workpiece transport. This creates a completely unmanned line, eliminating manual intervention across machining, measuring, discharging, and material handling. This system is a crucial step toward realizing your Smart Factory vision, ensuring stable production, labor saving, and major gains in productivity, utilization, and setup time reduction. (Note: The Full-Auto Version is currently under development for commercial release in 2026.)

Product Inquiry

Contact us