SYSTEM FEATURES Product Summary

Features of AIQ

Know the features of AIQ

Solve Problem by Connecting/Analysis/Feedback

AIQ is our original production management solution specialized for the manufacturing industry. It assists you in making a decision based on the collected data in real time, and perform improvement activities. It leads to efficiency and quality improvements in the manufacturing processes. AIQ enables you to manage production more efficiently in manufacturing, improve quality, reduce cost, and increase productivity. AIQ is flexible and customizable to meet your needs, making it a powerful tool to enhance competitiveness and promote sustained improvement.

Manufacturing Management

Automatic assignment of processes is possible taking into consideration the delivery time of each order and the load of facilities and workers.Mass Production Management

Actual results can be registered by a simple operation using a tablet terminal. Result Manager can analyze the results with graphs. Also, the actual cost, gross margin, progress rate and status for sales activities can be updated and checked easily.

DX Promotion the manufacturing industry / Introduction Video

Time(3:11)

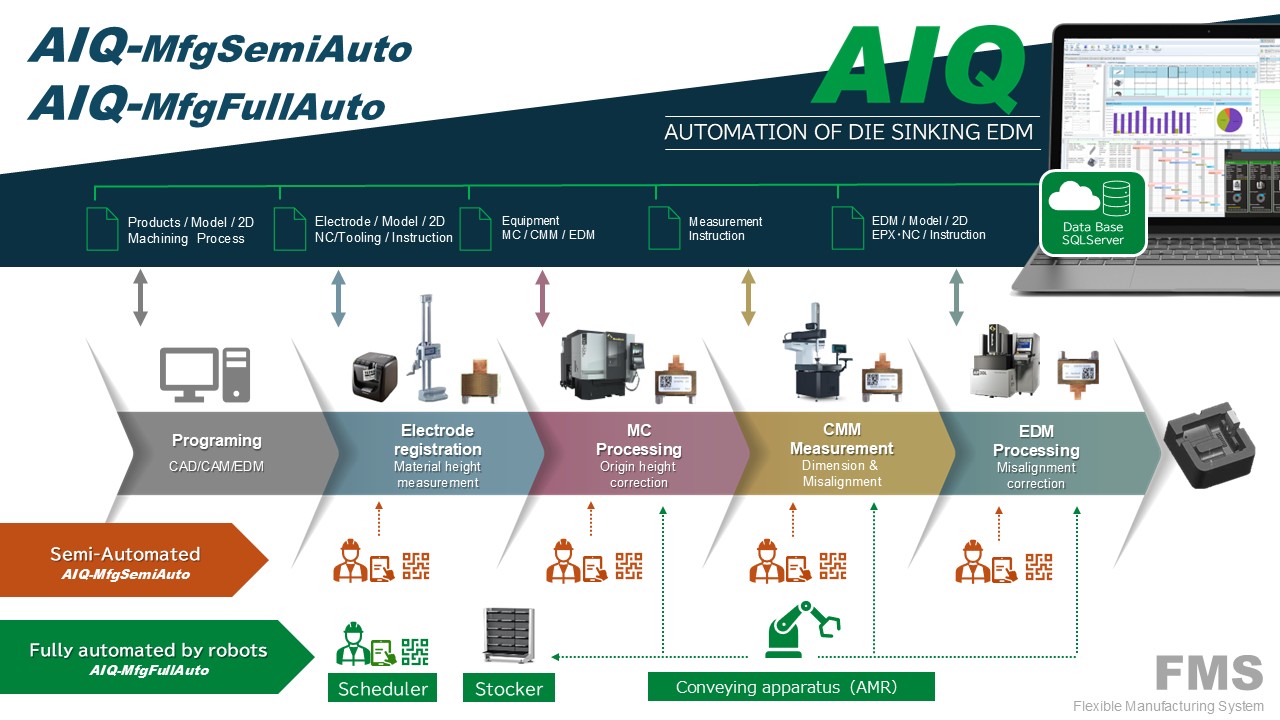

Flexible Manufacturing System NEW!!

From Human-Supported Automation to Human-Centric Full Automation

Facing unprecedented challenges in manufacturing—high-mix/low-volume, labor shortages, fierce global competition, and demand for shorter lead times—the need for streamlined EDM (Electrical Discharge Machining) is critical. Introducing AIQ-MfgSemiAuto / AIQ-MfgFullAuto, the integrated solution designed. By centralizing information management and automating die-sinking EDM, AIQ dramatically boosts productivity and quality. It simultaneously achieves:

- Reduced setup time

- Higher utilization

- Stable production

- Labor saving

AIQ offers a practical, phased approach to automation, providing a solid foundation for your Smart Factory. Future expansion to wire-cutting, grinding, and turning processes is planned. AIQ delivers the optimal digitalization and full-automation steps tailored to your shop floor needs.

AIQ-MfgSemiAuto

Centered around the AIQ database, the entire process—from design to electrode registration, MC machining, CMM measurement, and EDM machining—is seamlessly integrated. By enabling data access via QR codes and automatically applying correction values, on-site operations are simplified, helping to prevent human errors and improve productivity.AIQ-MfgFullAuto

From electrode registration onward, the processes are automatically coordinated by AMRs, collaborative robots, and stockers. Everything from workpiece transport and chucking to machining data transfer and retrieval is performed unmanned, enabling continuous operation and enhanced productivity through full automation.

- This product has been jointly developed with Sodick Co., Ltd.

- What is FMS?

FMS is a flexible production system that can handle high-mix, low-volume production. By combining NC machine tools, robots, and conveying systems, and centrally managing them with computers, different products can be efficiently produced.

System Configuration & Requirements

Module configuration for easy system expansion

Module configuration

System expansion is available to meet user's business demand even after introduction. We also welcome customization for specific needs.

* The system configuration has been changed since V15.3.

System requirements

OS |

Windows® 11 Pro 64bit |

DB |

SQL Server 2019 or later |

Office |

Excel2016 or later |

Field Terminal |

Smart Device(Android / iOS / Windows) |

Peripheral equipment |

Barcode Reader(USB type for PC connection recommended) |

Product Inquiry

Contact us