SYSTEM FEATURES Product Summary

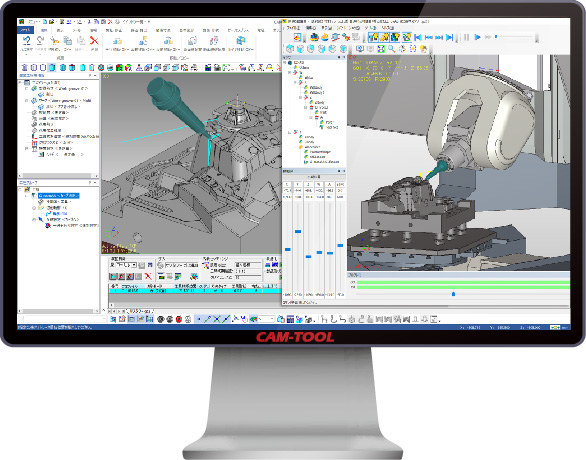

Feature of CAM-TOOL

Know the features of CAM-TOOL

Elite CAD/CAM System for Mold & Die Makers

CAM-TOOL addresses the needs of the Manufacturing Tooling Industry. CAM-TOOL addresses the sophisticated requirements of Mold & Die builders by offering unparalleled functionality using our powerful NC programming strategies that simply do not exist in other systems.

CAM-TOOL has more than 35 years history and has supplied approximately 2,700 companies, and 5,500 licenses. As CAD/CAM company, we are not only developing software, but also evaluating our new functions by actual cutting. We have 2 CNC machines in our Machine Technology Center, and we can make cutting samples, and we can do benchmark tests there.

Whether you’re doing High Speed Machining or Hard Milling, CAM-TOOL’s integrated surfacing modeling and NC programming techniques allow the user to generate toolpath to run your NC machine “Safely & Unattended” while providing unparalleled finish quality.

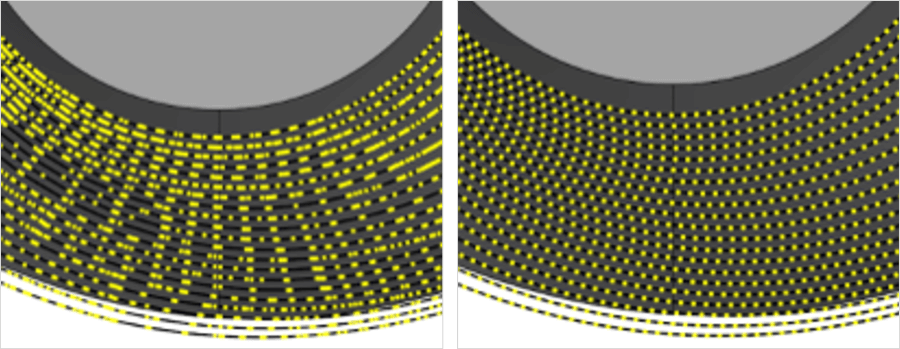

Surface calculation and polygon calculation

CAM-TOOL has both unique surface calculation technology and common polygon calculation technology. It addresses various milling demands such as precision, surface roughness, cost-effectiveness, deep milling, hard materials. CAM-TOOL achieves high precision and optimal milling by unique algorithm of "Surface calculation".

Cluttered component points (Left figure) / Constantly aligned points (Right figure)

Cluttered component points (Left figure) / Constantly aligned points (Right figure)

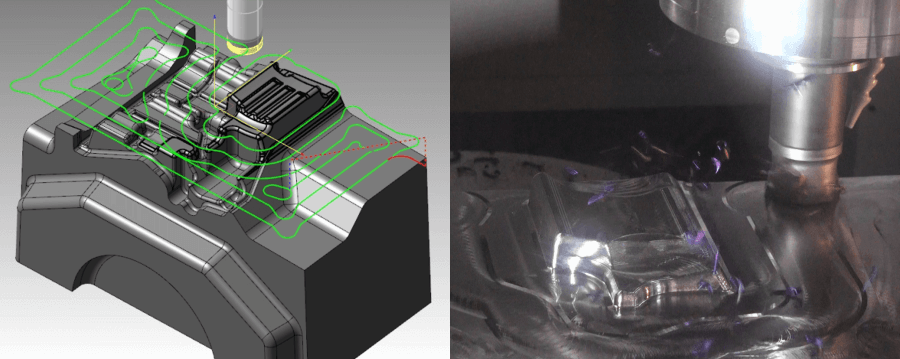

Highly efficient rough cutting by High feed radius cutter!!

“Z-level Rough Cutting with Multiple Tools (Round 2)” enables to prevent tool vibration and breakage of inserts by unique toolpath which has no partial contacts. It maximizes tool life and reduces cutting time even in machining hard materials.

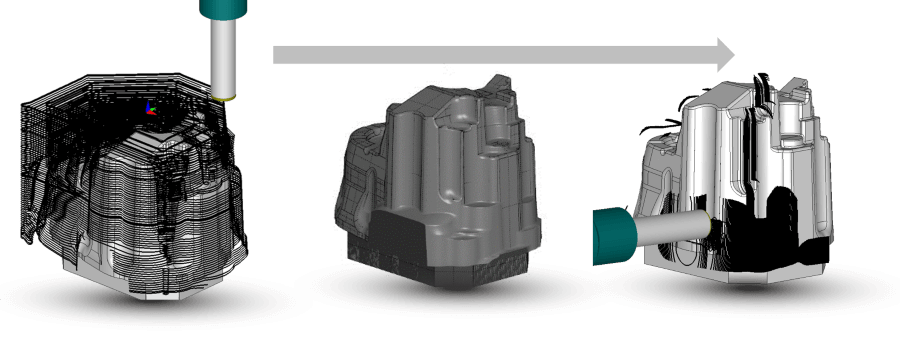

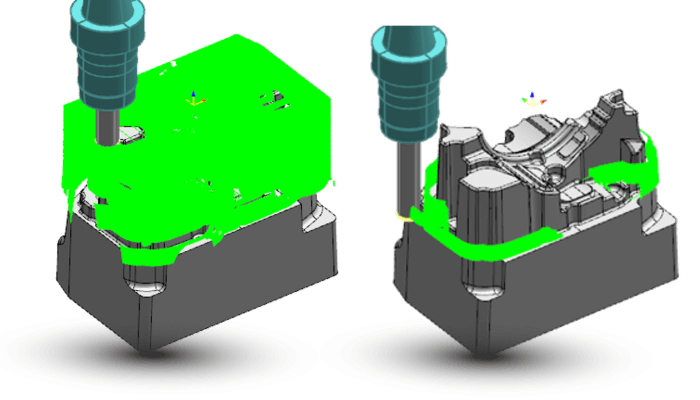

Automatic recognition of remaining area!!

Efficient second roughing needs to recognize stock of previous process accurately. "Solid in previous process" recognizes remaining area automatically and creates efficient toolpaths. It recognizes the remaining area even from different direction.

Process 1: Rough cutting → Stock shape → Process 2: Solid recognition from different direction

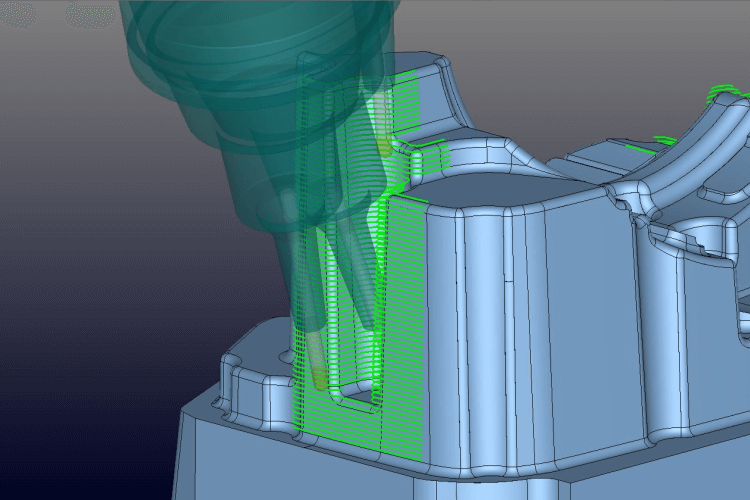

Avoids interference for specified tooling shape!!

Using with shorter protruding length is the best for every work but in particular case such as large, deep and hard shape, CAM operators have to use longer tooling. Since "Avoid tooling interference" generates internal shape to avoid interference for the specified tooling, it enables to maximize the machining area with the shorter tooling.

"Smoothing" function for high-quality 5axis machining!!

Change of tool axis direction in simultaneous 5axis machining makes significant effect to surface quality. CAM-TOOL has "Smoothing" function to move the tilt and rotation axis gradually, as a result, it achieves ultra high quality surfaces.

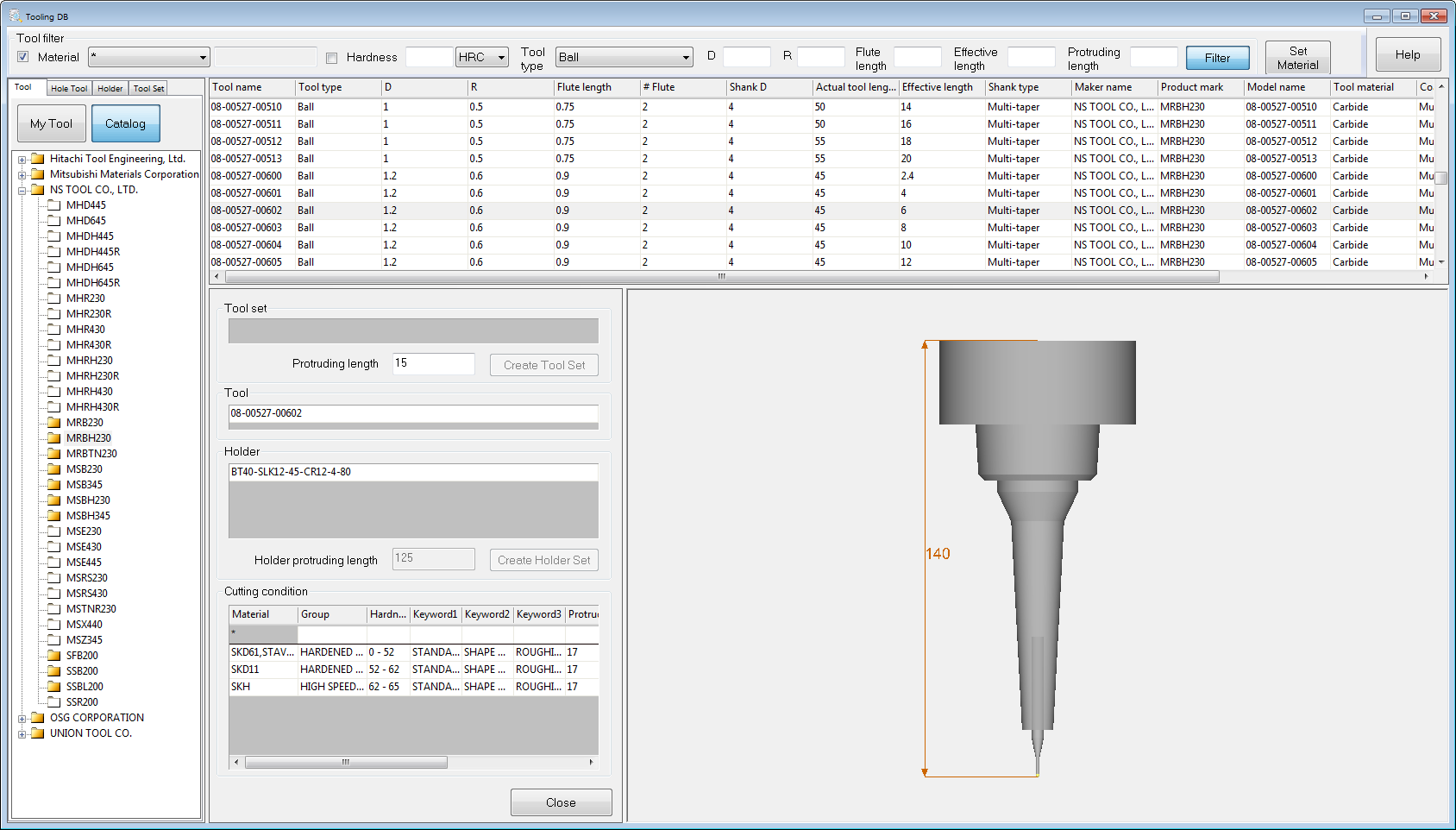

Tool and holder catalogs from major japanese manufacturers are available!!

Interference check and avoid interference needs accurate tool and holder shape definition. CAM-TOOL has "Tooling Database" which manages tools and its cutting conditions, and holder from major japanese tool and holder manufacturer. Tool shank shape can be defined with multiple taper shank and radius shape. Catalog data can be download from our support site.

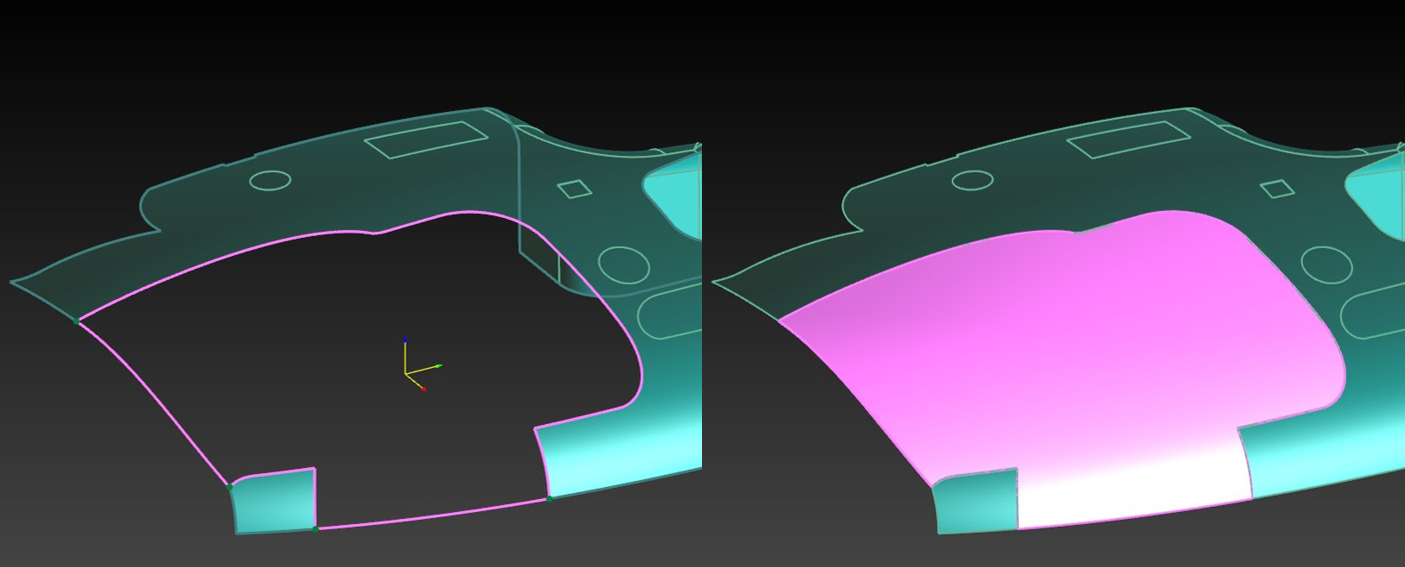

Own kernel's surface is equipped for excellent shape processing peculiar to mold machining!!

CAM-TOOL employs surface modelers that are superior to CAM. It is equipped with various shape evaluation and curved surface processing functions for the shape processing peculiar to dies developed uniquely by the company, and the shape editing like solid modeling can be carried out on the surface, so it can quickly handle the advanced modeling for dies indispensable for machining.

System Configuration & Requirements

Module configuration for easy system expansion

System configurations can be changed to meet your business demands by adding modules to improve the system‘s extensibility.

Main Module

Basis of CAM-TOOL application. IGES In/Out, DXF In/Out, STEP In/Out, STL In are included. Basic CAD functions for every configurations are included.

Learn MoreSurface modeling module for mold and die work. Creates models flexibly and efficiently from 2D drawings or extracting mold and die from imported 3D models.

Learn MorePost processor for 3axis machines. Various controllers and machines are working with CAM-TOOL.

Learn MoreHole module. Machines plates, deep holes, or cutting resistant materials flexibly.

Learn More2D and 2.5D module. 2D and 2.5D machining are necessary for mold and die making.

Learn More3D machining module. Elaborate CAM engine achieves high-precision and high-efficient rough cutting and finishing by smooth control points and tool load reduction. High-speed simulation module is available to prevent interferences.

Learn MoreEdit toolpaths as desired. Powerful commands such as Delete partially, Modify approach, Change direction, etc improve toolpath easily and safely.

Learn More3+2 axis CAM module for 5axis machines and setup change. Controls cutting direction and optimizes toolpath from multiple direction.

Learn More5 axis CAM module for simultaneous 5axis machining. Avoid interference and generate highly-precise toolpath.

Learn MoreOption Module

Translate CAD data from major CAD software accurately.

Learn MoreCreate surface like solid model. It maximize the speed of modeling by powerful commands.

Learn MoreEdit and repair STL data and create CAM data combining with surface models.

Learn MoreCreate electrode model for EDM machine. Output information for EDM machining such as reference point and offset the model for fluctuation gap.

Learn MoreChecks interference and stroke over of each axes. Simultaneous 5axis module includes this.

Learn MoreCreates nc program for On-machine Inspection using a touch probe. Reduces work by eliminating inspection set up. Base and Post-processor module are necessary.

Learn More"VERICUT interface" provides seamless operability from CAM-TOOL to Vericut.

Learn More"MAKINO Collision Safe Guard I/F" is the output module for "Collision Safeguard", monitoring & preventing function for machining collisions, equipped in "Professional 6" controller.

Learn MoreCalculate machining time within ±10% error by considering acceleration of the machine.

Learn More"AM (DED)"module equipped with a new processing mode that generates an DED-based additive manufacturing process. Simultaneous 5-axis CAM module is must installed.

Learn More"AM (MEX)"module equipped with a new processing mode that generates an MEX-based additive manufacturing process. Simultaneous 5-axis CAM module is must installed.

Learn MoreSpecial Specification

It is a packaged product for overseas local companies that are equipped with a proven CAM engine and pursuing standardization and level equalization of operations.

Learn MoreModel viewer for CAM-TOOL. Possible to check Model, tool path, stocks, NC program. And also, it output NC program with post processor module.

Learn More"CAM-TOOL AM (DED)" is a combined CAM system that supports simultaneous 5-axis control, equipped with a new processing mode that generates an DED-based additive manufacturing process.Base / Modeler / 2.5DCAM / 3DCAM / CL editing / positioning 5-axis CAM / simultaneous 5-axis CAM / Post Processor / machine simulation module is installed.

Learn More"CAM-TOOL AM (MEX)" is a combined CAM system that supports simultaneous 5-axis control, equipped with a new processing mode that generates an MEX-based additive manufacturing process.Base / Modeler / 2.5DCAM / 3DCAM / CL editing / positioning 5-axis CAM / simultaneous 5-axis CAM / Post Processor / machine simulation module is installed.

Learn MoreModule configuration

| Utilization | Viewer |

Modeling |

Hole |

2.5D Milling |

3D Milling |

3+2 Milling |

5 Axis Milling |

AM |

|---|---|---|---|---|---|---|---|---|

| Base | ||||||||

| Modeler | ||||||||

| Postprocessor | ||||||||

| HOLE | ||||||||

| 2.5D CAM | ||||||||

| 3D CAM | ||||||||

| CL-Editor | ||||||||

| 3+2 Axis CAM | ||||||||

| 5 Axis CAM | ||||||||

| AM (DED/MEX) |

Required Selection Select one or more

System requirements

Native correspondence is carried out at the 64-bit OS environment. It was released from memory restrictions and comfortable work environment is realized also to large scale.

OS |

Windows 10 Pro / Windows 10 Pro for Workstations / Windows 10 Pro Education Windows 11 Pro / Windows 11 Pro for Workstations / Windows 11 Pro Education *Windows 11:Supported versions Ver18.1 or more |

CPU |

Multi-Core Processor |

RAM |

16GB or more |

HDD |

80GB or more |

VIDEO |

3D Acceleration OpenGL board(NVIDIA® RTX / Quadro) |

DISPLAY |

Resolution:1920x1080 (Recommendation) *Min 1280x1024 / Max 3840x2160 |

New Function of CAM-TOOL

Version Up Information

Product Inquiry

Contact us