USER CASE STUDY

SHOWA MOLD & ENGINEERING CO., Ltd.

Location:Tokushima, Japan Website:www.showaseiki-ind.co.jp

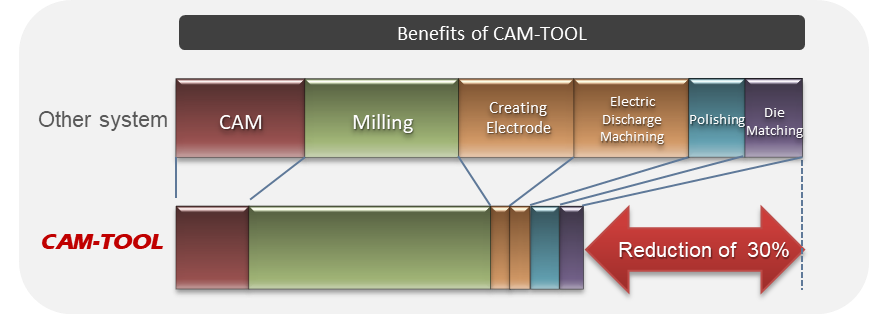

A plastic injection mold maker reduced costs "by 30%" by introducing CAM-TOOL!!

SHOWA MOLD & ENGINEERING CO., Ltd, which mainly manufactures large plastic molds for automotive such as instrument panels, bumpers, and extension headlamps, has succeeded in significantly improving man-hours by introducing CAM-TOOL.

Problem

They had been working on shortening the process to complete the product, such as the CAM process, tools, and machining methods, but with the previous CAM system, there was a limit to improvement in cutting conditions and methods and so on.

Mr. Fukuyama, Managing Director

Mr. Fukuyama, Managing Director

Solution

- With the previous CAM system, when cutting with a tool with a short protrusion length, they needed to create a surface on the model shape to avoid interference, but with CAM-TOOL, they can generate toolpath easily for areas where the cutter tool and holder do not interfere.

- The previous CAM system was not able to detect accurately the remaining area, causing chattering in the corner area. So, they needed to cut in while gradually reducing the cutter tool diameter, which lead to the large number of cutter tools. On the other hand, CAM-TOOL can accurately detect the remaining area of the previous process with its unique feature "stock calculation", insert R at the corner, and generate the re-machining toolpath with less cutting load fluctuation.

- Before the introduction of CAM-TOOL, they did a lot of electric discharge machining (EDM). But CAM-TOOL can generate smooth toolpath composed of uniform component points, which is quite suitable toolpath for mold manufacturing, and also has a lot of functionalities such as to control the feed rate depending on the cutting load. As a result, stable cutting has been achieved with L/D Ratio 90, and they have been able to cut directly the areas that had been done by electric discharge machining previously. Furthermore, the surface burnt by electric discharge machining has also been reduced.

Results

-

Simplification of CAM operation

Reduction of CAM operational mistakes

Improvement in cutter tool life -

Reduction of the number of cutter tools

Improvement in cutter tool life - Significant reduction in EDM process and polishing process

Comments by Mr. Murahara in MC department

“Soon after the introduction of CAM-TOOL, we noticed stable machining can be performed without the machine tool vibrating or cutter tool chattering during machining as before. In addition to improving the machining efficiency, the machining quality has also been greatly improved, and the man-hours for mold assembly and fitting have been reduced to 1/2 to 1/3 compared to the previous level.”

Comments by Mr. Sugihara in CAM department

“Currently, we're using 9 seats of CAM-TOOL and only 2 seats of previous CAM system that we used 20 seats before. We will keep taking on new challenges with CAM-TOOL.”

Mr. Murahara (MC dep.) Mr. Sugihara (CAM dep.)

Mr. Murahara (MC dep.) Mr. Sugihara (CAM dep.)

Product Inquiry

Contact us