USER CASE STUDY

Nagoya Precision Mold Co., Ltd.

Location:Aichi, Japan Website:www.nagoya-sk.co.jp

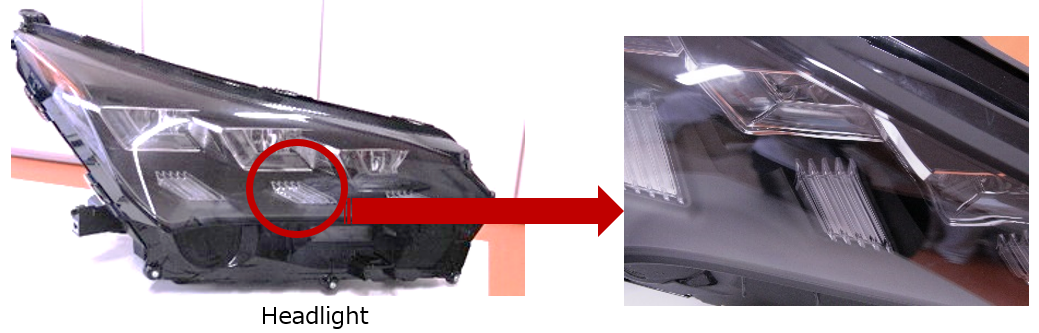

An automotive headlight mold maker reduced their man-hours "by 40%" by introducing CAM-TOOL 5 Axis.

Since its establishment in 1975, Nagoya Precision Mold has been engaged in the design and manufacture of plastic injection molds for automobile headlight parts such as lenses, inner lenses, reflectors, extensions, light guides, etc. They have three plants in Japan and factories in Vietnam and Indonesia too. The introduction of CAM-TOOL 5 Axis accomplished full-scale mold production with efficient 5 Axis machining, which has led to significant results in reducing lead times.

Problem

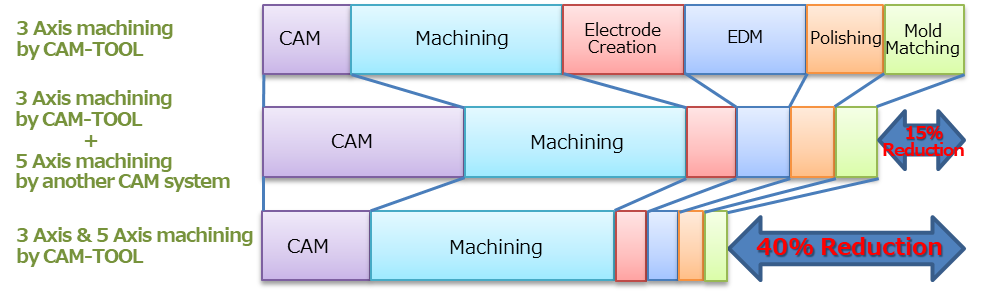

Previously, they had used two kinds of CAM systems separately: CAM-TOOL for 3 Axis machining, and another CAM system for 5 Axis machining. However, they found out that not only data convertibility and compatibility difficulties between two systems but also the instability of 5 Axis toolpaths generated by another CAM system had caused to increase in CAM programmers' work.

Implement CAM-TOOL 5 Axis

They re-considered the 5 Axis CAM system comparing four kinds of CAM systems including CAM-TOOL. Then, they decided to take CAM-TOOL 5 Axis in the end since they realized CAM-TOOL has lots of advantages, such as a high-quality surface finishing with stable toolpaths, high usability with various cutting modes, and many more, not to mention that it allows seamless operation between 3 Axis and 5 Axis functions with a single system, reducing CAM programmers’ workload.

- Solution 1

CAM-TOOL can convert 3 Axis data to 5 Axis data easily. - Solution 2

CAM-TOOL has a reliable machine simulation function. - Solution 3

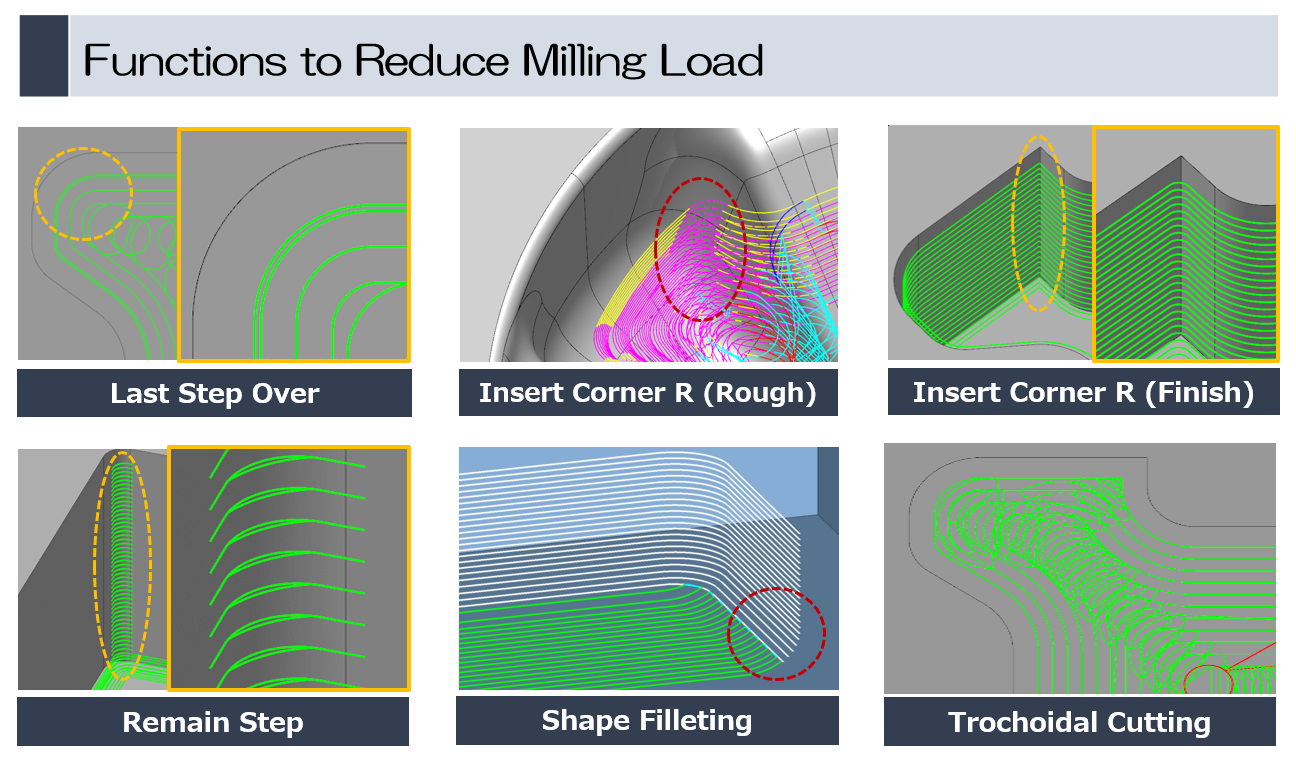

CAM-TOOL has a smoothing function for 5 Axis machining that suppress any sudden change in tool vector as well as a lot of functions to reduce cutting loads.

Result

- Not only man-hours for creating data but also data corrections caused by toolpath errors in the previous 5 Axis CAM operations that had been their big problem have been drastically decreased.

- They can create the machining data easily without any data exchange with another simulation software before the actual milling.

- When machining areas where the toolpath has an edge such as a concave area, the functions such as "Insert Corner R" to avoid sudden cutting load fluctuations have achieved the smooth motion of the machine tool, which has led to the better surface finishing quality.

Comments from Nagoya Precision Mold

Mr. Sonoda thinks man-hours have been reduced by around 50% in terms of the CAM operation alone. He also said workloads in EDM process have decreased by 30%, and there are even some cases in which EDM process is no longer necessary at all depending on mold types. In addition, since the surface finishing quality has been improved, the polishing time has also decreased.

Product Inquiry

Contact us