USER CASE STUDY

SANKO LITE INDUSTRIES CO., LTD.

Location:Kanagawa, Japan Website:www.slkco.jp

An injection mold maker reduced their man-hours for mold model editing "by 40%" by introducing CAM-TOOL function "Surface Plus".

SANKO LITE INDUSTRIES CO., LTD., designs and manufactures the molds, and then processes, paints, and assembles the housing parts of smartphones, automobile components, plastic tableware, and many other plastic products. They provide several types of molds, such as two-color molds capable of different materials molding, LIM molds for injecting waterproof packing into molded plastic parts, and others. In the two-color mold, dimensional matching accuracy for each combination of 2 different movable side dies and 2 identical stationary side dies is required. LIM is also a special mold that requires high precision on the sealing face, so as not to allow the resin to leak out. Both molds can not be accepted without high precision and accuracy.

Problem

Just after the cavity and core models are provided, many elements are added to the models. For instance, there are holes such as bolt mounting holes, tapped holes, ejector pin holes in the core, and wire-cut contours for oil grooves in the sliding portions or for inserts. If CAM operation is done with the original model data, the generated toolpaths may not be always appropriate, with the possibility of incorrectly interfering with other holes, etc. Therefore, model editing is required to delete those unnecessary elements in advance, but this model editing operation was a big issue for them in terms of their man-hours.

Solution

One of the CAM-TOOL's optional CAD functions "Surface Plus", which can do CAD operations like Solid-Modeler, had them reduce their manhours of the model editing.

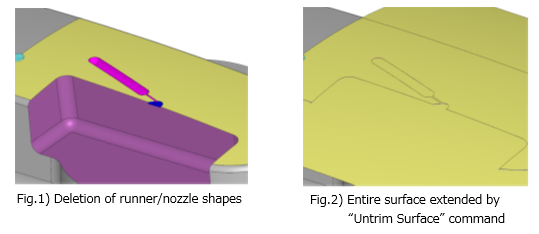

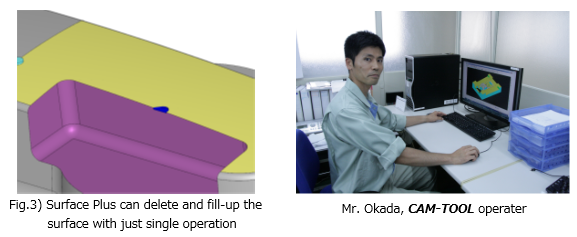

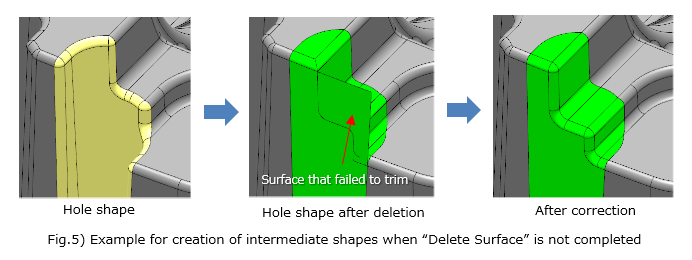

Mr. Okada said there are several unnecessary elements for CAM processing in the model received from the Design Group, such as the ejector pins, runners, and mounting holes for bolts, but “Delete Surface” function in “Surface Plus” is very effective for deleting those elements. Especially the trimming operations after removing holes or shapes with trimmed contour across multiple surfaces have been reduced drastically, improving their operationality (Fig.4).Mr. Okada also said, unlike Solid-Modeler, “Surface Plus” creates intermediate shapes if possible, even if the deletion doesn't completely succeed, so all he needs to do later is a further correction on some parts, which is one of the big advantages of using “Surface Plus (Fig.5).

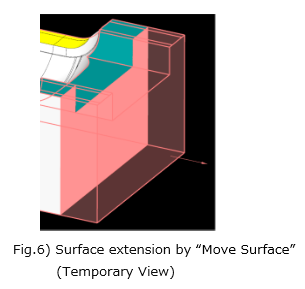

Moreover, he also utilizes "Surface Plus" function to create additional surfaces for generating more efficient toolpaths. With “Move Surface” command to specify the target surface to move, he can extend multiple surrounding surfaces simultaneously with a single operation (Fig.6).

Result

By installing “Surface Plus”, their mold model editing labor has decreased drastically and the required man-hours have been reduced by 40%. This means that lead time has been successfully shortened by around 15% from the viewpoint of total man-hours for the Mold Division, which is a great achievement.

Product Inquiry

Contact us